LED light panels are used almost everywhere now—shops, hotels, bars, display counters, and many decorative surfaces. They spread light evenly, stay thin, and don’t heat up much, which makes them popular for long hours of commercial use. But even with a good lifespan, an LED panel can still run into problems. Maybe a corner looks dim, maybe the driver burned, or the whole sheet doesn’t light up anymore. When that happens, the big question comes up: repair it or replace it?

This is not always an easy call. It depends on how the panel was made, how serious the fault is, and whether the brand has a solid structure behind it. Raymates, known for UL、ETL、CE、RoHS certifications and stable LED sheet production, builds products that are friendly to both repairs and full replacement. Their flexible LED sheets, steady chips, and good light consistency give users a clearer path when dealing with faults.

What Factors Determine Whether an LED Light Panel Can Be Repaired?

Before doing anything, it helps to understand why the problem happened. Some faults are simple and can be fixed quickly. Others affect the entire sheet and make repair less practical.

A technician usually checks three main areas.

Internal Component Condition

Many small issues come from things like loose solder points, bent connectors, or a few LED nodes burning out. These problems are usually fixable. Re-soldering or swapping a small section can bring the panel back to normal. Panels built with even LED spacing and stable chips—like Raymates LED sheets—usually have cleaner layouts, which helps during troubleshooting.

Driver and Power Compatibility

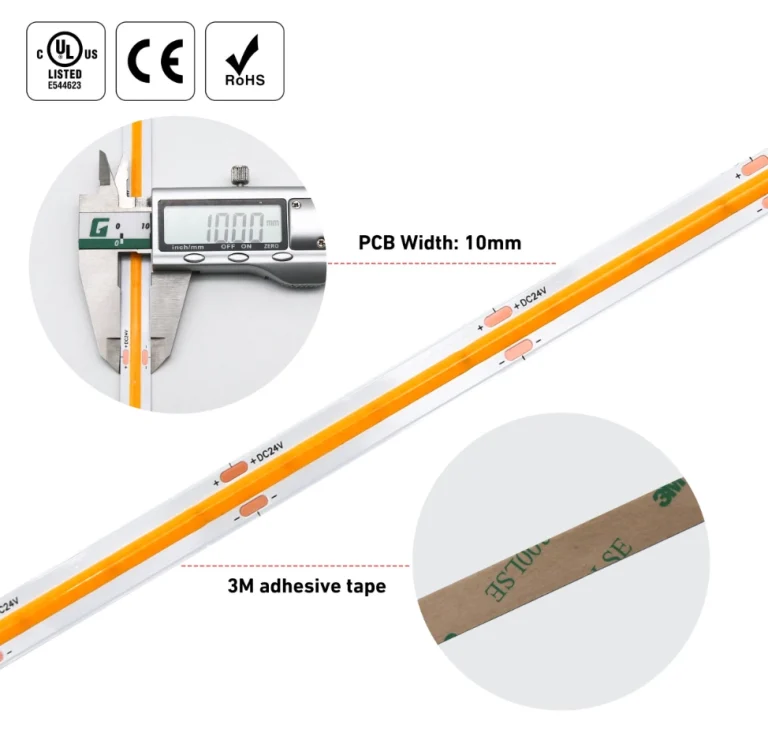

A lot of flicker or sudden blackout problems begin at the power supply instead of the LED sheet. If the driver stops giving stable voltage, the panel reacts instantly. Replacing the driver often solves the issue. Panels running on common low-voltage systems such as 12V or 24V also make the process smoother because parts are easier to match.

Panel Construction and Flexibility

How the panel is built matters more than people expect. Flexible LED sheets that have clear cut lines or foldable parts are easier to repair because broken sections can be removed without touching the whole sheet. Rigid panels sealed under plastic layers tend to crack or warp when opened, so repairs become risky. In those cases, replacement makes more sense.

When Does Repairing LED Panels Become More Cost-Effective?

Repairing is common when the damage is small and the rest of the sheet still works properly. Many commercial spaces prefer repairing first because it avoids downtime and keeps the original setup intact.

Minor Electrical Faults

If the issue comes from small wiring damage, loose ends, or one connector failing, fixing it takes little time. These problems do not affect the rest of the sheet, so repair is usually enough.

Localized Damage

LED sheets often come with cuttable and modular layouts. This means if only a tiny area loses brightness or changes color, that section can be replaced instead of removing the whole panel. This is especially helpful in flexible LED sheets where each cut zone works like its own little lighting unit.

Modular LED Designs

Panels that have one-light-one-cut structures or easy connection points naturally support long-term fixing. Raymates LED sheets follow this kind of setup, allowing users to change only the faulty part and keep the rest of the lighting untouched. This reduces labor time and avoids wasting material.

When Should LED Panels Be Replaced Instead of Repaired?

Sometimes replacing the panel is simply the smarter choice. Repair might be possible, but the result may not stay stable for long, especially if the damage reaches deep layers of the panel.

Severe Panel Damage

If the PCB is burned, heavily bent, or cracked, repairing it is not likely to hold up. A damaged board causes uneven heat flow, leading to repeated failures. Replacement saves both time and future trouble.

Aging or Low-Efficiency LEDs

LEDs slowly dim as they age. If the whole sheet shows uneven brightness or inconsistent color temperature, repairing only a few points won’t make everything match again. A new panel provides a cleaner, more even look.

Non-Standard or Outdated Models

Some older LED panels use unusual chips or drivers that are hard to find now. Replacing these parts becomes expensive and time-consuming. Many hotels, retail stores, and display setups prefer replacing the whole panel so the lighting stays consistent across all areas.

How Do Raymates LED Panels Improve Repairability and Replacement Efficiency?

Raymates products are built for long-term use in commercial spaces. Their LED sheets focus on brightness, stability, and simple installation, which naturally makes repairs easier and replacements quicker.

Cuttable and Flexible Design

The Lensed LED Sheet and Matrix LED Sheet both use clear cut marks and a flexible layout. Installers can trim them to match different surfaces—curved, straight, or uneven. This design also helps during repairs: the faulty zone can be removed, and the rest stays untouched.

High Uniformity and Stability

Raymates uses high-CRI chips (CRI≥90) and consistent chip spacing to give smooth, even light. This layout helps avoid dark edges and random bright points. A stable chip line also reduces surprise failures. With UL and CE certifications, the panels work reliably in shops, hotels, and long-running displays.

Versatile Product Line

The range of LED sheets fits many scenes—from stone backlighting to display shelves, lightboxes, and large decorative walls. This helps businesses use similar panels across many spaces, making repair, replacement, and stocking spare parts much easier.

Which Raymates LED Light Panels Are Best for Long-Term Reliability?

Raymates provides several LED sheet types, but the following two models are widely used in high-end commercial and decorative lighting projects.

Lensed LED Sheet for Premium Backlighting

The Lensed LED Sheet produces smooth and bright backlighting without dots. It works especially well behind onyx stone, marble counters, cosmetic display tables, and hotel bars. The built-in lens spreads light evenly, even when the material in front is thin. Because it’s flexible and cuttable, installers often use it for areas with odd corners or detailed shapes.

Matrix LED Sheet for Large-Format Installations

The Matrix LED Sheet uses a grid layout that keeps light stable over big spaces. It suits hotel lobby walls, retail features, big lightboxes, and display backgrounds. Its modular wiring lets technicians replace parts quickly, and the high brightness helps spaces look clean and modern even from a distance. Many users choose it for long-running installations where steady lighting is needed.

FAQs

Q1: How long can LED light panels usually last?

A: Most commercial LED panels run for roughly 30,000–50,000 hours. Panels from brands like Raymates often last longer due to better chips, smoother heat control, and stricter factory checks.

Q2: Can LED sheets be cut anywhere during installation?

A: No. LED sheets must be cut only at the marked lines. Raymates Lensed LED Sheet and Matrix LED Sheet clearly show these points so the wiring stays safe and the brightness remains consistent.

Q3: Will a replacement LED panel match the older panels already installed?

A: Yes, in most cases. Raymates keeps color temperature and brightness consistent across product batches, so new panels blend smoothly with existing setups as long as voltage and drivers match.