LED panels see common use in store displays, hotel setups, backlit counters, and building lights. Their thin shape, steady light spread, and small power draw turn them into a favored option. However, even solid LED panels can run into problems after extended operation or faulty setup. For many purchasers and fitters, the main query stays straightforward: if an LED panel breaks down, does fixing it work, or should you swap it out instead?

Grasping the way LED panels get assembled, the spots where breakdowns tend to occur, and how modular items get planned out can make this choice far easier. For brands like Raymates, which stress adaptable LED sheets for business lighting tasks, the chance to fix ties directly to the item’s build and how it’s used.

What Causes LED Panel Failures?

Before settling on any fix, you need to pinpoint the real source of the trouble. Most LED panel breakdowns do not happen by chance. Instead, they stem from just a handful of typical problems.

Common Electrical Issues

Power-related troubles rank among the top causes why LED panels quit. These frequently involve shaky power sources, wrong voltage fits, or worn-out drivers. In various setups, the LED panels themselves keep working fine, whereas the driver or link piece has given out.

In setups with low power like 12V or 24V LED sheets, slack wires or weak solder spots might cause blinking or partial darkness. As time passes, warmth and shaking can loosen those links, particularly in business areas where lights run for many hours each day.

Physical Damage And Wear

Harm from physical forces counts as another key reason. LED panels fitted beneath marble, within counters, or behind show walls might deal with squeezes, flexing pressure, or hits during fitting or upkeep. Slim LED sheets bend easily, but folding them past the advised curve can still harm the inner paths.

Water contact also worries users in pubs, hotels, and spots with food. Dampness buildup can gradually harm solder joints and links, leading to spotty breakdowns that people often mix up with faults in the LED chips.

Component Degradation Over Time

Quality LEDs still have a limited run time. Following years of steady work, the light level might fade, color warmth could shift, or single LEDs might stop. This does not always spell doom for the whole panel. In setups with modular LED sheets, wear tends to stay in one spot, so you can target fixes or swap just parts.

How Do You Diagnose A Faulty LED Panel?

After you figure out likely reasons, the following move is to check the issue. A solid check cuts down on wasted time and skips needless swap expenses.

Visual Inspection And Symptom Checklist

You always start with a close look. Spots of darkness, patchy brightness, or color changes usually signal local LED or path troubles. Blinking points to shaky power, while total darkness might mean the driver quit or the main path broke.

Signs like scorch marks, rust, or raised solder areas show clear physical or power strain. For bendable LED sheets, hurt cut spots count as a usual problem, above all when cuts happen beyond the marked lines.

Using A Multimeter For Voltage Tests

Once you do the visual scan, simple power checks help nail down the fault. A multimeter lets you swiftly see if the right power reaches the LED panel. If power shows at the entry but the LEDs stay dark, the trouble likely sits inside the panel.

Checking separate parts of the panel works well for modular LED sheets. This way, you spot if one length failed or if the whole path got hit.

Testing Backlight And Driver Components

You must not overlook drivers. Plenty of LED panels get tossed just because the driver stopped. Switching in a driver you know works often beats deep power checks in speed.

Raymates LED sheet options pair up with reliable, standard drivers from the field, so swapping a driver turns simple and low-hazard when you troubleshoot.

Can LENSED LED SHEET Panels Be Repaired?

Once you diagnose, the odds of fixing depend a lot on how the item got made. LENSED LED SHEET items from Raymates include fix-friendly traits that match drawn-out business use.

Replaceable Lenses And Modular Design

LENSED LED SHEET panels rely on a piece-by-piece setup with LEDs spaced out evenly and light-bending lenses. When harm stays in a set area, you can often swap single sections rather than pull the full panel.

Such a setup proves handy in beauty counters, stone light backs, and shelf displays, where panels sit in set builds. Spot fixes skip tearing down big show surfaces.

Driver And Circuit Component Swap

In lots of actual jobs, the LED chips hold up well. Swapping drivers, links, or hurt path parts brings back full work. Since Raymates items stick to steady power rules and uniform plans, matching parts come easy to find.

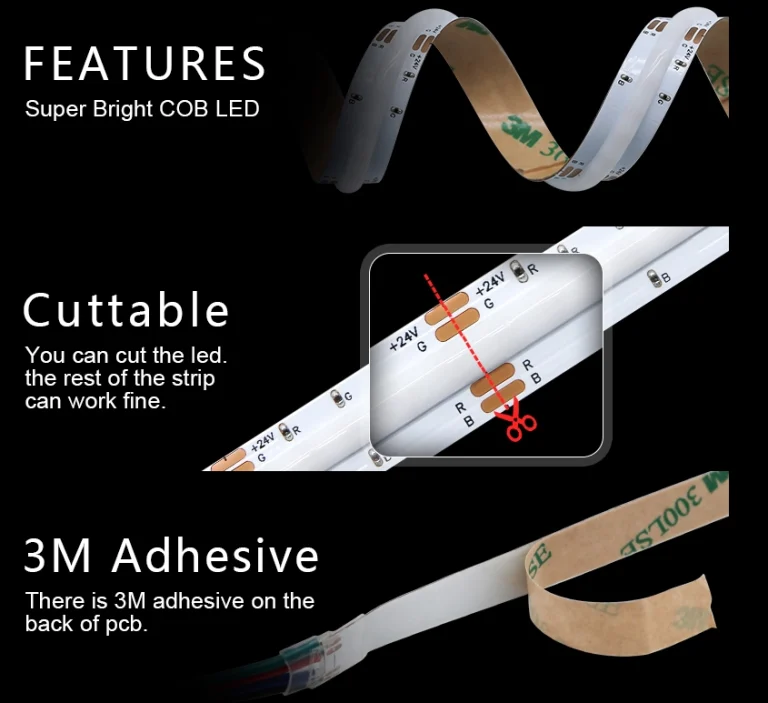

The cuttable style aids fixes too. You can trim off bad lengths neatly at set cut spots, then link them back with right connectors or solder work.

When Replacement Is More Cost-Effective

You should not fix every LENSED LED SHEET panel. If harm covers wide spots, or if the panel nears its end run, swapping makes more sense cost-wise. In top spots where even light and color matter most, some wear might still call for a total update.

Are Repairs Possible For MATRIX LED SHEET Systems?

MATRIX LED SHEET items use a distinct build, yet they give useful fix paths when you handle them right.

Troubleshooting Matrix LED Fault Points

Sheets in matrix style spread power over several nodes. If one node quits, the trouble might stay boxed in without hitting the full panel. This lets you spot faults more sharply, but it calls for close checks.

Dark patches in set patterns often mean node faults over driver woes.

Repairing Individual LED Segments

In MATRIX LED SHEET setups, single lengths can at times get fixed or skipped, based on how the wires run. This helps in big installs like light boxes or building panels, where changing the whole sheet would cost a lot and take time.

Right care counts a great deal. Bad fixes might throw off power flow and steady run over time.

Benefits Of Modular MATRIX LED Architecture

The piece-by-piece build of MATRIX LED SHEET items backs growth and upkeep. For jobs needing regular changes or long runs, this style cuts stop time and makes after-service easier.

Raymates stresses even plans and power specs, which lets fitters do neat fixes without tough math work.

What DIY Tips Improve Repair Success?

You can handle DIY fixes in many spots, but only if you take care. Small slips can shift a minor issue into lasting harm.

Safety First: Power Off And Protective Gear

Every fix must begin with cutting all power fully. Even setups with low power can spark shorts or part damage if you touch them without thought. Gear against static works best when you deal with LED chips and control boards.

Detailed Documentation Of Steps

Before you cut or take off any part, note down wire routes and power sides to avoid mix-ups when you put it back. Shots you snap while taking apart often save effort down the line.

Tools that fit the job matter too. Weak solder gear or cheap links can cut trust even after a good fix.

When To Seek Professional Help

If the trouble hits tricky control setups, big installs, or faults that keep coming, expert aid beats trying alone. Raymates offers tech advice and tailored fixes for those spots, so buyers skip guesswork that hikes costs.

Conclusion

Fixing LED panels does not boil down to a plain yes or no. The reply hinges on the breakdown kind, item build, and use needs. Thanks to piece-by-piece styles like LENSED LED SHEET and MATRIX LED SHEET, Raymates turns fixes and upkeep more doable for business and building jobs.

Learning when to fix, when to swap, and how to check troubles right guards both light work and lasting spends.

FAQ

Q1: Is it safe to repair LED panels on-site?

A: On-site fixes stay safe if you cut power fully and use right tools. For big or tricky systems, expert aid gets advised.

Q2: Can a flickering LED panel always be repaired?

A: Blinking usually stems from driver or link troubles. Often, swapping the driver or mending wires clears it up without panel changes.

Q3: Are Raymates LED sheets designed for long-term maintenance?

A: Yes. Raymates LED sheet items stress piece-by-piece plans, steady power rules, and cuttable styles, which back simpler fixes and long runs.