Lighting isn’t just about brightness anymore. In modern spaces, it’s about atmosphere, usability, and how easily the product fits into a real-world project. LED sheets have become one of the most versatile tools in the lighting industry. They’re slim, cuttable, and flexible enough to slide behind a marble countertop or a cosmetics display case without showing up as clunky hardware. But if you’ve ever browsed through product catalogs, you’ll know one thing: not all LED sheets are made the same. Picking the right one for your project can be a little tricky.

Raymates, a company with more than a decade of experience in LED manufacturing, offers some of the best-in-class LED sheets for both commercial and decorative applications. Their MATRIX LED SHEET and LENSED LED SHEET are two excellent examples. Before you make a purchase, let’s break down the key questions you should be asking.

What Factors Should You Consider Before Selecting an LED Sheet

Material and Flexibility Options

First, think about the surface you’ll be working with. LED sheets come in flexible or semi-rigid designs. A flexible sheet can wrap around curved displays or fit into furniture edges. A rigid one works better for flat, structured panels. For instance, if you’re outfitting a bar counter with rounded corners, a flexible option like Raymates’ MATRIX LED SHEET will save you hours of cutting and adjusting.

Power, Voltage, and Efficiency Levels

Not every project runs on the same voltage. Small retail cabinets may use 12V setups, while larger installations might need 24V for stable brightness. One common mistake is mismatching the driver power supply — something installers complain about more than they should. Raymates helps here by offering sheets compatible with different voltage systems, so you don’t have to gamble on whether your driver will fry the panel.

Certification and Quality Standards

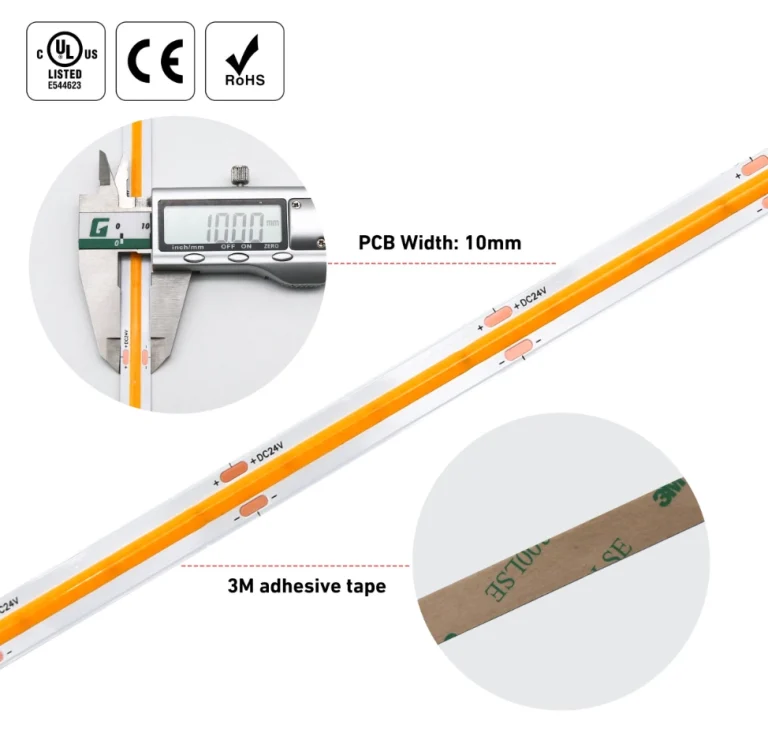

Here’s a detail many people ignore: certifications. But when your project is destined for a luxury hotel or an overseas client, it matters. Raymates LED sheets are UL, CE, and RoHS certified, which basically means they’re tested for safety, quality, and environmental standards. If you’ve ever had a client ask for proof of compliance halfway through a project, you’ll understand the relief of having that paperwork ready.

How Do LED Sheets Differ by Application

Interior Design and Decorative Lighting

Think about five-star hotel lobbies or modern coffee shops. Designers want lighting that looks invisible but feels intentional. A slim LED sheet can hide behind a frosted glass wall or a stair riser to create that glow-without-the-source effect.

Retail Displays and Branding Solutions

Retailers love LED sheets because they make products pop. A cosmetics brand, for example, doesn’t want shadows on its packaging. The MATRIX LED SHEET, with its one-light-one-cut design, helps store designers create uniform displays without reordering dozens of customized panels.

Backlit Stone and Countertops

Backlit onyx or marble countertops are a growing trend. The challenge? Stones aren’t evenly translucent, so you’ll see dark patches if the lighting isn’t consistent. That’s where Raymates’ LENSED LED SHEET comes in. Its lens structure spreads light evenly, solving one of the biggest pain points in stone lighting projects.

Why Is Light Distribution Important in LED Sheets

Uniform Illumination Across the Surface

Nothing screams “cheap” more than uneven lighting. Customers immediately notice bright centers and dark edges. A well-designed sheet spreads light evenly so the surface feels smooth to the eye.

Prevention of Dark Spots and Edge Shadows

Cutting corners is tempting — literally. But when installers trim an LED sheet and forget about spacing, edge shadows appear. Raymates designs pre-marked cut points, so even after trimming, the sheet maintains a consistent look.

High Color Rendering for True-to-Life Colors

In environments like clothing stores or art galleries, color accuracy matters. A shirt that looks burgundy under poor lighting may appear almost brown. With a CRI above 90, Raymates’ sheets reproduce colors faithfully, so products appear as they are meant to.

Which Raymates LED Sheet Fits Your Needs

MATRIX LED Sheet for Flexible and Cuttable Projects

The MATRIX LED SHEET is a flexible, cuttable option that’s perfect for irregular surfaces. Think curved bar counters, display cabinets, or furniture edges. It’s lightweight, about the thickness of a coin, and can be trimmed without messing up the electrical flow. A contractor once told us he finished an entire retail display with Matrix sheets in a single afternoon — what normally takes a day and a half.

LENSED LED Sheet for Even Illumination and Diffusion

The LENSED LED SHEET is designed for diffusion. Its built-in lens technology eliminates hotspots, making it the go-to choice for backlit stones, signs, or translucent surfaces. Imagine installing this behind a hotel reception desk made of onyx — the glow looks natural, without harsh pinpoints.

Customizable Options for Special Applications

Sometimes, standard products don’t cut it. Maybe you need a logo-shaped sheet or a non-standard color temperature. Raymates offers OEM/ODM customization, though keep in mind — custom molds often mean higher minimum order quantities. It’s great for large-scale branding projects but not the most budget-friendly for one-offs.

How Can You Ensure Easy Installation and Long-Term Reliability

Cuttable and Bendable Design Advantages

LED sheets that allow cut-and-fit installation save time and reduce waste. Raymates’ products come with clear cut guides — no guesswork. If you’ve ever burned through a panel by cutting at the wrong spot, you’ll appreciate this.

Secure Mounting and Adhesive Solutions

Flexible panels tend to rebound on curves. Standard double-sided tape isn’t enough. Installers often switch to 3M industrial adhesives or even screws. Raymates acknowledges this reality, recommending proper fixation methods instead of pretending tape will work everywhere.

Compatibility with Drivers and Power Supplies

A driver mismatch is a nightmare. Raymates supports a variety of driver setups, reducing those “back to the warehouse” moments. Their sheets pair with both constant voltage and constant current drivers, depending on project needs.

What Are the Cost and Maintenance Considerations

Long Lifespan and Reduced Replacement Costs

A typical Raymates LED sheet lasts up to 50,000 hours. That’s roughly 5 years of continuous use. Fewer replacements mean fewer complaints and fewer late-night calls from clients.

Energy Efficiency for Lower Bills

LED technology cuts energy use dramatically compared to traditional lighting. For businesses running lights 12–16 hours a day, that difference adds up quickly.

Minimal Maintenance with Durable Materials

Moisture and dust can ruin a panel over time. Raymates builds their products with high-quality soldering and protective designs to avoid oxidation or flickering issues, which are surprisingly common in cheaper products.

Where Can LED Sheets Create the Greatest Impact

Hotel and Hospitality Lighting

Hotels use LED sheets for feature walls, lobby counters, and even staircases. It’s the subtle lighting that guests don’t notice directly but always remember.

Commercial and Retail Environments

From jewelry counters to high-end fashion stores, LED sheets highlight merchandise and create a clean, upscale look. Retailers often say lighting sells the product before the sales team does.

Residential and Home Improvement Projects

For homeowners, LED sheets are finding their way into kitchen islands, under-cabinet lighting, and even bathroom mirrors. The effect is cozy yet modern — and installation doesn’t require tearing down walls.

FAQs

Q1: Can LED sheets be cut to any size?

Yes, most Raymates LED sheets are cuttable at marked points. Cutting outside those marks can damage the circuit, so always follow the guidelines.

Q2: Do LED sheets work outdoors?

Standard models are best for indoor use. For outdoor or humid areas, higher IP-rated solutions are recommended. Raymates provides advice on waterproofing if your project requires it.

Q3: How long do Raymates LED sheets usually last?

With proper installation, they typically last over 50,000 hours — about 5 years of non-stop use, or much longer under normal conditions.