LED sheets are getting more common for many lighting jobs. They’re bendy, use little power, and shine bright. Whether you’re adding soft lights to your home, making flashy store displays, or doing a home project that saves energy, changing LED sheets can give you the right lighting for what you need.

Can you cut and change an LED sheet? Yes! This guide shows how to cut and change LED sheets. It helps you get the best from these handy products.

Understanding LED Sheets

Before we start cutting and changing, let’s see what LED sheets are. And why they’re so popular.

What Are LED Sheets?

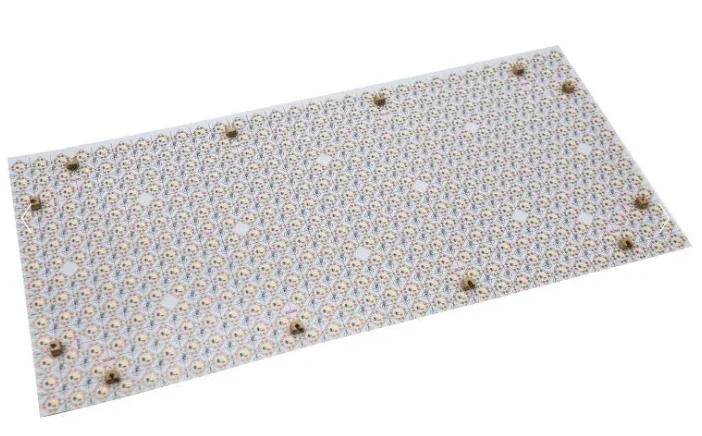

LED sheets are bendy, thin boards with many LEDs spread out on them. They give even lighting. These sheets come in different sizes. You can use them for pretty lights or useful ones. For your project, you can find LED sheets in one color or many. Like RGB or white that you can adjust.

They’re used a lot for things like back lights, building lights, display lights, and more. The bendy nature and easy use of LED sheets make them good for many places. Like stores or homes.

Types of LED Sheets Available

LED sheets come in different kinds for different uses:

Flexible LED Sheets: Good for bending around curves or odd shapes.

Ultra-Thin LED Sheets: Slim and light. Great for tight spots where space is small.

Customizable LED Sheets: Made to cut for specific fits. They offer lots of creative ideas.

Can You Cut LED Sheets?

One nice thing about LED sheets is you can change them. You can cut them to fit your space or design. But before you start, think about a few important things.

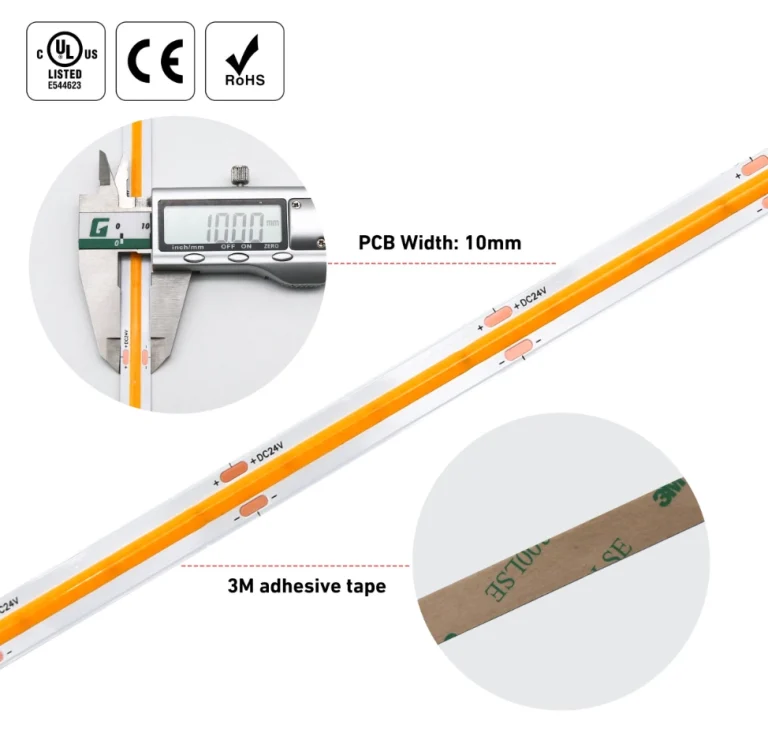

Designated Cutting Points

Most LED sheets have clear lines where you can cut safely. These marks let you trim without hurting the wires inside. Cutting these sheets is normal for many setups. It cuts down waste. And makes the light fit just right.

For example, RAYMATES has LED sheets with marked cut spots. You can make custom sizes. And not lose how they work. Whether it’s for a kitchen counter, a store display, or a light box you make, these sheets can be shaped to your needs.

Tools Required for Cutting

To cut LED sheets, you need the right tools for clean cuts. Here’s what you’ll need:

- Sharp scissors or a knife: These cut through the sheet without harming the wires.

- Cutting mat: Protects your table and keeps cuts straight.

- Ruler and marker: For measuring and marking where to cut.

Step-by-Step Cutting Guide

Preparation: First, measure the spot where you want the LED sheet. Use a ruler to mark the cut lines on the sheet.

Cutting: Use sharp scissors or a knife to cut along the marks. Go slow to avoid rough edges or breaking the wires.

Post-Cutting Care: After cutting, seal the open ends to protect them. Use silicone or other seals to keep out water and dust. This is key for outdoor or damp places.

Customizing LED Sheets

Once you cut the LED sheet to the right size, it’s time to change it more. Here are ways to make it fit your project.

Bending and Shaping

LED sheets are bendy. They can fit curved spots. But watch the bend limit to not break the wires. Bend gently. Avoid sharp turns that can snap the LEDs.

For example, under a kitchen counter, you can bend the sheet around corners. It gives even light without dark spots.

Connecting Multiple Sheets

For bigger areas or tricky setups, you might link many LED sheets. Do this by soldering the links or using clips. If soldering is new, clips are easy. They snap together fast without special tools.

Also, make sure the power supply fits the total power of all sheets. For RAYMATES products, check their site for guides and charts to pick the right power.

Integrating with Controllers

To get changing effects, color switches, or dim lights, add a controller to your LED sheet. RAYMATES LED sheets work with many controllers. You can change brightness, colors, or even sync with music or motion. Pick a controller that matches the sheet’s voltage and power.

Applications of Customized LED Sheets

LED sheets are really flexible. They fit many uses. Here are some ideas for changing them.

Signage and Branding

Custom LED sheets are great for lighted signs and logos in businesses. Cutting and shaping lets you fit exact designs. The even light makes it look pro.

For example, a store can use LED sheets for glowing product displays. A restaurant can make a lit logo with bendy LED sheets.

Architectural Lighting

LED sheets are used a lot for building lights. Like back lighting walls, ceilings, and counters. Their thin design lets you hide them without messing up the look.

A common use is lighting behind stone counters. It gives a fancy, modern feel.

Decorative and Ambient Lighting

For homes or stores, LED sheets make soft lights. Cut and shape them to fit around furniture, under stairs, or along ceilings for cool effects.

Safety and Maintenance Tips

Electrical Safety Precautions

When using LED sheets, match the voltage right. Secure the links. Always check the power rating before connecting. If unsure, ask a pro to avoid problems.

Maintenance Guidelines

LED sheets don’t need much care. But check for dust, dirt, and water now and then. It helps them last longer. Use a dry cloth to clean the surface gently. Make sure links stay tight.

Conclusion

Changing LED sheets is a good way to get the right lighting for many uses. From custom displays to building lights, the ideas are endless. Follow the right cutting and changing steps. You can get the full use of LED sheets. Create nice lighting for your next project.

FAQ

Q1. Can I use any tool to cut LED sheets?

A: No, it’s important to use sharp scissors or a utility knife to ensure clean cuts. Avoid using dull blades, as they could damage the LED strips or create uneven cuts.

Q2. How do I connect multiple LED sheets together?

A: You can connect LED sheets by either soldering them or using connectors. Ensure that the connections are secure, and always check that the power supply can handle the combined wattage of all connected sheets.

Q3. Are LED sheets safe to cut and install by myself?

A: Yes, as long as you follow the guidelines for cutting and installation. Make sure to cut along the designated lines, seal the exposed ends, and use the correct power supply. If you’re unsure about any step, don’t hesitate to consult a professional.