COB strips are used everywhere now. People stick them under shelves, behind TVs, inside shop counters, or around hotel features. The strips bend easily and can be trimmed to fit almost any corner, which is why they’re so common. But when a COB strip rips right at the cut line, one side may go dim or start flickering. It looks like a tiny break, yet it causes frustrating problems. Knowing why it happens and how to deal with it helps avoid wasted time and replacements. Raymates, a long-running manufacturer with solid production experience, also makes stronger COB strips that handle bending and cutting better, reducing the chance that a strip tears in the first place.

What Causes COB Strips to Tear at the Cut Line?

When a strip snaps at the cut mark, there’s usually a simple reason behind it. The copper pads and tiny circuits in the strip are thin. A small cutting mistake or a bit too much bending pressure can damage them. Once that area cracks, light output becomes unstable. Understanding these reasons makes it easier to avoid the same damage next time.

Excessive Bending Force on the FPC

The flexible PCB inside a COB strip can only bend so far. When someone pushes the strip hard around a sharp edge, the copper tracks stretch. After a few seconds, or sometimes later, the tracks break. Long strips hanging loosely also pull down under their own weight. All that stress adds up. The cut point becomes the weak part, and it tears more easily.

Incorrect Cutting Tools or Uneven Cutting Angles

Many people use regular household scissors to cut COB strips. But scissors that aren’t sharp enough squeeze the copper pads instead of cutting them clean. A slanted cut or cutting outside the printed line can also damage the contact pads. When the pads become uneven, reconnecting the strip gets tricky, and the strip might not light up correctly afterward.

Weak Copper Pads Found in Low-Quality COB Strips

Some cheaper strips use very thin copper layers. These peel off with just a bit of bending. Bad adhesive also makes the strip lift from the surface, and when people push it down again, the strip bends at odd angles. That motion increases the chance of tearing. Raymates COB strips are made differently. They use stronger FPC and stable bonding methods reviewed under ISO9001, so the cut areas stay firm even after shaping and bending.

How Can a Torn COB Strip Be Repaired Safely?

A broken COB strip doesn’t always need to be thrown away. Many tears can be fixed with basic tools. The right repair depends on how clean the tear is and whether the copper pads are still there. Spending a bit more care on this step usually brings the strip back to normal.

Re-Soldering the Damaged Copper Pads

For people who have handled a soldering iron before, soldering is the most reliable fix. A fine soldering tip melts a tiny bit of solder to reconnect the two sides of the torn strip. This makes a small metal bridge across the pads. But the job must be gentle. Too much heat lifts the fragile copper pads from the FPC. A drop of flux helps the solder flow smoothly, but slow, careful movement is important.

Using Clip Connectors for Fast Rejoining

Not everyone wants to solder. Clip connectors solve that. These clips have small metal contacts that grab the copper pads and reconnect the strip without heat. They’re simple, quick, and good for beginners. But they only work when the pads are clean and still visible. If the tear is rough or the pads peeled away, clips won’t help.

Reinforcing the Cut Point With Heat-Shrink or Tape

After reconnecting the strip, giving that spot extra support helps. A short piece of heat-shrink tubing or even a strip of electrical tape holds the area steady. This keeps the joint from moving too much, and the repaired point stays stable longer.

Which Tools and Materials Are Needed for a Reliable Repair?

Fixing a delicate part like a COB strip gets much easier with proper tools. Even basic tools reduce the chance of damaging the strip further. They don’t guarantee perfect results, but they definitely make the work smoother.

Small Soldering Kits With Fine Tips

A small-tip iron, thin solder wire, and tweezers help control heat and handle tiny pads. These tools are common among installers because they make quick field repairs possible.

COB-Focused Connectors and Soft Extension Wires

COB strips, including Raymates models, sometimes have narrow pad spacing. Connectors designed specifically for COB strips have slimmer contacts that match the gaps. Soft extension wires also help when the repaired area needs room to bend or move during installation.

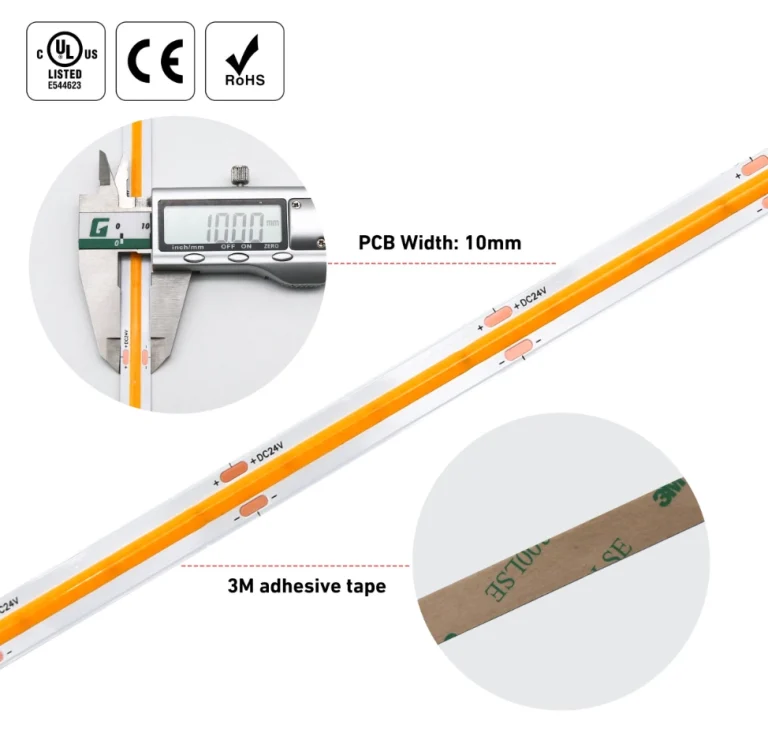

Strong Adhesive Tape and Heat-Resistant Backing

After repairing a strip, keeping it flat is just as important as reconnection. A layer of fresh 3M tape, silicone glue, or aluminum channel backing stops extra movement. Many installers place the repaired area inside an aluminum profile so the strip stays fully supported.

When Should a Damaged COB Strip Be Replaced Instead of Repaired?

Not every torn strip deserves a repair. Some breaks are too large or too messy to fix properly. Checking the tear closely usually makes the choice simple.

Severe Oxidation or Copper Pads Missing Entirely

If the copper pads look greenish, dull, or are gone, there’s nothing left to solder or clamp. Pads wear down faster in damp places. When the pads are worn out, repair becomes nearly impossible.

A Larger Section of the Strip Stops Working

Sometimes the tear affects not just the cut line but a longer part of the strip. When multiple small sections fail, repairing each one takes longer than replacing the whole strip. A new strip gives a cleaner and more stable result.

Repeated Breaking Because of Weak Materials

If the strip snaps again during simple handling, the issue is the strip quality, not the repair. Thin copper, weak glue, and poor FPC structure make some COB strips too fragile. Switching to stronger options like Raymates COB strips stops this cycle of repeated breaks.

Which Raymates COB Strips Offer Better Durability and Reduce Tearing Risk?

Starting with a stronger COB strip helps avoid future problems. Raymates, founded in 2009 and equipped with SONY SMT machines along with UL, CE, and RoHS certifications, produces COB strips with solid bending strength and smoother light output. These strips hold their shape during installation and resist tearing, even in narrow or curved areas.

Here are three Raymates COB strips that customers pick when they want longer-lasting performance.

SUPER LONG COB Strip for Long, Stable Lighting Runs

The SUPER LONG COB Strip suits long-distance lighting projects. With fewer connection points, the whole run stays stable and easier to mount. It’s a good choice for hotel hallways, retail shelves, and long decorative lines.

MINI SIZE COB Strip for Narrow Corners and Tight Spots

The MINI SIZE COB Strip is slim and bends naturally without stress. It’s designed for tight areas where regular strips get pushed too hard. This strip works well for cabinets, wall grooves, or custom furniture edges.

COLORFUL COB Strip for Flexible and Creative Lighting Effects

The COLORFUL COB Strip fits places where color changes and frequent adjustments are needed. Bars, gaming setups, and small event spaces often use it because it handles bending and shifting better than many standard strips.

FAQ

Q1: Can a torn COB strip still work after a repair?

A: Yes. As long as the copper pads remain in place, a solder joint or connector usually restores the light.

Q2: Why do COB strips tear even when cut at the printed line?

A: Because bending force or weak copper layers are often the real cause—not the cutting itself.

Q3: How do you avoid tearing in the future?

A: Avoid tight bends, use stable mounting surfaces or channels, and pick stronger strips such as Raymates COB models.