LED light panels have gained popularity in commercial areas, hotels, retail setups, and building lighting tasks. Their slim build, uniform glow, and versatile fitting choices suit contemporary styles well. Yet, just like other lighting setups, these panels can face troubles as time passes. Issues such as flickering, irregular brightness, warmth accumulation, or excessive brightness can impact looks and function.

Grasping the main reasons behind these troubles aids in skipping unneeded swaps and interruptions. With dependable LED sheet options from Raymates, like the LENSED LED SHEET and MATRIX LED SHEET, numerous typical problems get addressed right from the beginning instead of fixed afterward. This guide covers usual LED light panel concerns and straightforward methods to handle them in actual setups.

What Causes Flickering In LED Light Panels?

Flickering stands out as one of the most obvious LED panel issues. It disturbs visual ease, particularly in retail areas, hotel entrances, or illuminated stone features where constant light counts a lot.

Prior to swapping panels, examining the entire system proves helpful. Flicker typically arises from auxiliary parts rather than the LED sheet on its own.

Power Supply Or Driver Problems

An ill-matched or subpar power supply often sparks this. LED panels need steady voltage and current. If the driver fails to provide reliable output, light variations occur.

Raymates LED sheets come in various low-voltage versions, such as 12V and 24V. These options enable better matching with common drivers in worldwide tasks. Selecting a verified driver with sufficient power reserve cuts down flicker chances during extended operation. Thus, a simple review of driver capacity frequently resolves the matter without altering the panel.

Incompatible Dimmers Or Controls

Not every dimmer pairs effectively with LED panels. Standard dimmers made for halogen or incandescent bulbs might lead to flickering or noise when linked to LED arrangements.

For tasks involving variable brightness, combining Raymates LED sheets with controllers suited for LEDs remains essential. Systems based on PWM dimming or 0–10V generally deliver superior results and offer gentler light shifts. Consequently, changing the control unit often corrects flicker right away.

Faulty Connection Or Wiring

Unsecured connectors, badly joined solder points, or rusted contacts can disrupt current passage. Such problems appear more often in setups with extended cable lengths or repeated on-site trimming.

Raymates LED sheets include distinct cut guides and firm solder areas. These features assist installers in minimizing wiring mistakes. Even so, verifying connectors and tightening terminals should form a standard part of the troubleshooting process.

How Do I Fix Dim Or Uneven Lighting On My LED Panels?

Irregular brightness can render premium displays incomplete. Spots that stay dark, shadow streaks, or fading light levels become particularly evident in beauty stations and illuminated boxes. This concern usually stems from fitting specifics instead of LED breakdowns.

Check For Loose Or Incorrect Wiring

If power spreads unevenly over the panel, certain sections get reduced current. As a result, dim zones or steady light decline emerge.

Opting for parallel wiring over lengthy series links aids in sustaining uniform brightness. Raymates LED sheets support modular patterns. This design simplifies balancing power over broad expanses. Therefore, a wiring assessment typically yields fast gains.

Evaluate LED Sheet Type And Mounting Method

Various tasks demand specific LED sheet forms. Slender diffusion layers or limited mounting depths might expose bright spots or shadows.

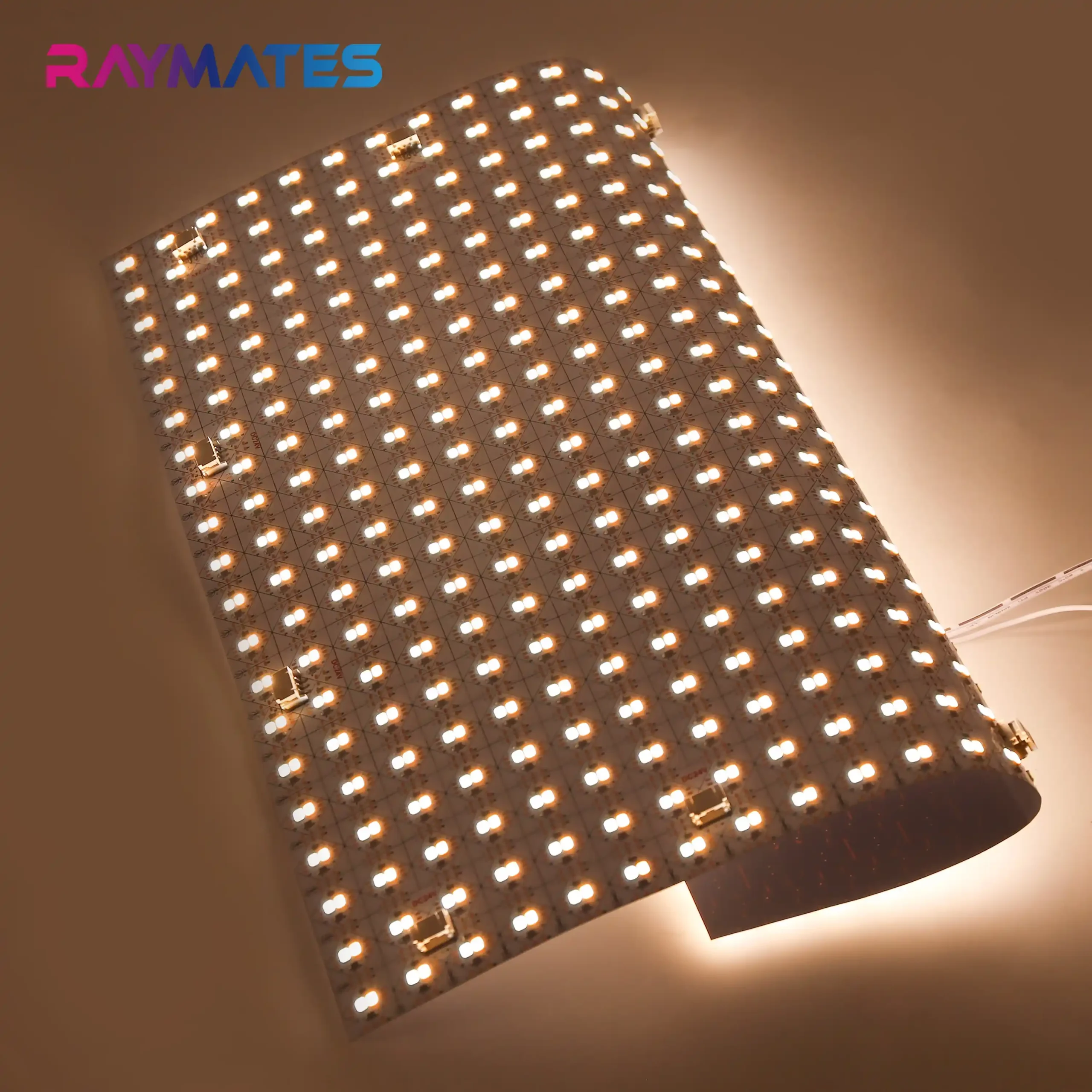

The MATRIX LED SHEET employs a grid-pattern LED arrangement that disperses light more uniformly over expansive zones. It performs reliably in sizable backlit panels where evenness proves vital. Hence, aligning the LED sheet style with the illumination area often remedies uneven results without incorporating additional coverings.

Upgrade To Higher-Performance LED Panels

Earlier or low-density LED sheets might falter in fulfilling brightness demands as years go by. Under those conditions, updating proves wiser than tweaking drivers or diffusers.

Raymates LED sheets provide close LED intervals and elevated CRI performance. These qualities ensure steady brightness and hue consistency throughout the panel. Such features benefit retail and lodging environments greatly, where precise colors hold importance.

Why Is My LED Light Panel Overheating?

Warmth accumulation curtails LED durability and triggers hue changes. Although LEDs operate cooler than conventional lighting, inadequate warmth handling can still generate concerns. Overheating generally indicates fitting or system planning shortcomings. According to a 2023 study from the International Energy Agency, heat buildup in poorly ventilated LED installations can reduce efficiency by up to 20%, underscoring the importance of proper heat management systems

Poor Heat Dissipation Design

Extremely slim panels appear neat, but they require routes to release warmth. Attaching LED sheets straight to non-porous bases can confine heat.

Raymates LED sheets rely on solid base materials that facilitate reliable heat movement. Combining them with aluminum supports or air circulation spaces allows warmth to dissipate naturally. Often, minor spacing adjustments create substantial improvements.

Inadequate Ventilation Around Fixtures

Enclosed lightboxes or airtight stone panels might suffer from poor airflow. Gradually, inner temperatures climb and influence output.

Incorporating air vents or employing warmth-releasing frames can decrease working temperatures. In upscale fittings, designers frequently neglect this aspect during planning.

Excessive Current From Power Source

Pushing LED panels too hard might enhance brightness briefly, yet it results in overheating and prompt breakdowns.

Raymates offers power tailoring, which lets tasks harmonize brightness and power consumption without exceeding safe boundaries for panels. Adhering to specified power levels preserves light steadiness and prolongs operational duration.

How Can I Reduce Glare Or Hot Spots On LED Light Panels?

Excessive brightness and distinct light points diminish ease and sight quality. These troubles occur frequently in shallow fittings or ornamental lighting featuring mirroring surfaces. Addressing them typically involves improved light management over increased intensity. LEDs consume up to 75% less energy than incandescent bulbs, which is confirmed by the U.S. Department of Energy. This significant reduction in energy use not only lowers operating costs but also reduces the heat generated by traditional lighting.

Use Diffused Or Lensed LED Sheets

The LENSED LED SHEET from Raymates aims to mellow light emission and distribute it evenly. Integrated lenses assist in lessening sharp brightness while upholding intensity. This suits marble worktops, bar edges, and shelf displays where unavoidable direct light persists.

Optimize Light Distribution With Matrix Panels

The MATRIX LED SHEET delivers equilibrated spacing that curbs bright spots over vast regions. Its framework promotes seamless light merging, even using slim diffusion coverings. This method excels in promotional lightboxes and expansive ornamental panels.

Adjust Installation Angle And Placement

At times, excessive brightness relates not to the panel but to its location. Minor tilt modifications or greater separation between the LED sheet and diffuser can boost sight comfort. Hence, evaluating positions prior to permanent securing conserves effort and resources down the line.

What Maintenance Tips Prevent Common LED Panel Failures?

Many LED panel issues develop gradually. Routine inspections enable early detection and safeguard the outlay. Basic upkeep practices frequently lengthen system longevity by several years.

Regular Cleaning Of Panels And Components

Dust layers obstruct warmth escape and lessen light emission. Mild cleaning maintains panel vividness and coolness. This holds special relevance in busy commercial venues with heavy visitor flow.

Periodic Inspection Of Drivers And Cables

Drivers and cables wear out quicker than LED sheets. Examining for warmth harm, unsecured links, or rust assists in averting abrupt malfunctions. Swapping a driver ahead of time costs less than overhauling the full panel.

Choosing Quality LED Sheets Like Raymates Products

Trustworthy parts lessen upkeep demands initially. Raymates LED sheets undergo testing via ISO9001 standards and gain approval for international markets. This renders them apt for enduring tasks. Investing in quality early frequently avoids unexpected issues later.

FAQ

Q1: Are Raymates LED sheets suitable for curved or irregular surfaces?

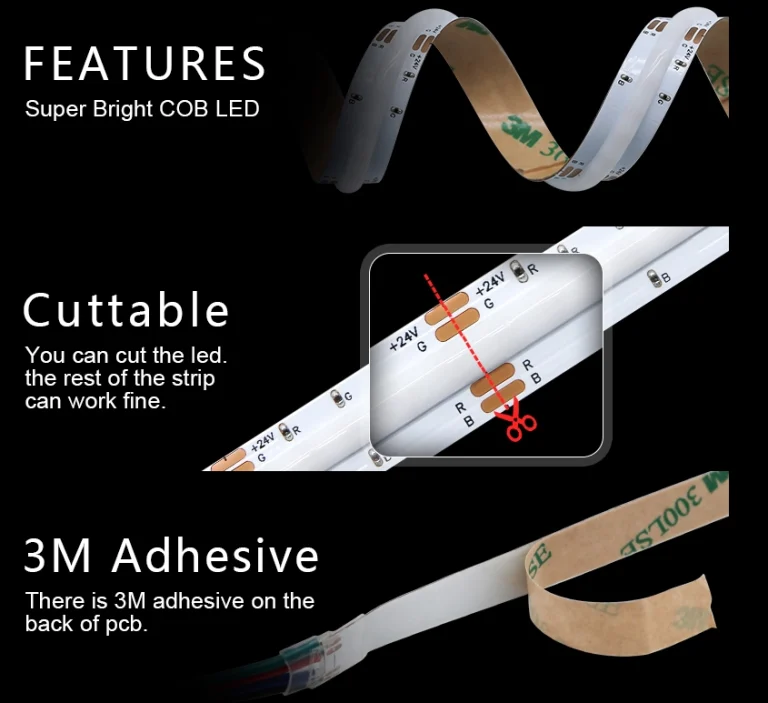

A: Yes. Raymates LED sheets possess flexibility and cuttability, which render them fitting for bent counters, pillars, and tailored display forms.

Q2: Which LED sheet is better for large backlit panels?

A: The MATRIX LED SHEET suits large zones due to its uniform light spread and lowered chance of bright spots.

Q3: How long do Raymates LED light panels typically last?

A: When fitted correctly and matched with appropriate power, Raymates LED sheets endure up to 50,000 hours of use. This qualifies them for sustained commercial applications.