LED panels serve many purposes in retail setups, hotels, lightboxes, and decorative backlighting since they provide steady, uniform illumination while consuming little power. Yet, numerous lighting issues stem not from the products themselves, but from setup errors that gradually harm the panels right from the beginning. Problems like inconsistent brightness, quick color changes, or abrupt blackouts frequently link back to faults during the initial assembly.

Knowing these typical errors allows you to prevent squandered supplies, extra labor expenses, and dissatisfied clients. Even better, selecting LED panels built for actual setup scenarios can stop most of these troubles before they arise. Raymates, backed by more than ten years in LED sheet production, crafts its LED panels to minimize field hazards and ensure reliable lighting performance over extended periods.

Why Do Incorrect Power Choices Damage LED Panels So Quickly?

Issues tied to power rank high among the usual causes of early LED panel breakdowns. Plenty of setups appear solid during first checks, but then they develop flickering or lifeless spots after just a few weeks. Such troubles typically begin with choices made about the power supply.

Prior to examining attachment or cabling specifics, power picking calls for thorough care, particularly in big backlighting zones or ongoing setups.

Mismatched Voltage and Current Selection

Picking the incorrect voltage offers a swift path to cutting short the life of an LED panel. Low-voltage LED sheets demand exact pairing with the driver, and even a minor mismatch might not trigger immediate breakdown, yet it builds unseen strain on LED chips and solder connections.

Certain installers figure that greater voltage yields stronger light, but in truth, excess voltage sparks heat accumulation, erratic output, and irregular wear throughout the panel. Raymates LED sheets carry plain labels showing working voltage choices like 12V and 24V, which assist installers in skipping uncertainty when preparing.

Ignoring Power Load Calculations for Large Panels

Big lightboxes or extended bar counters commonly link several LED sheets in series, and without accurate power load figuring, a single driver might exceed its secure limits. As a result, this leads to flickering when running at peak brightness or unexpected halts following prolonged runtime.

Raymates suggests figuring total wattage including a buffer for safety, instead of operating drivers at maximum capacity, and this approach maintains steady brightness while dodging strain in daily extended use.

Stable Driver Compatibility With Raymates LED Sheets

Raymates LED sheets pair well with reliable constant-voltage drivers that see wide use in business lighting, and even current spread over the panel aids in preventing hot areas and light fade near the borders.

In expansive backlighting tasks, MATRIX LED SHEET stands out as a top pick because of its organized pattern and even power movement, which simplifies expanding setups without power wobbles.

How Does Poor Mounting Lead to Uneven Light and Early Failure?

Although you might have the right power feed, faulty mounting can subtly wreck LED panels as time passes, since mechanical pressure, surface spaces, and flimsy securing ways all influence light dispersal and heat release.

When mounting flaws show up, fixing them proves tough without pulling out the whole panel.

Uneven Surface Contact and Panel Deformation

LED sheets aim to lie flat on the attachment base, but when placed on bumpy or grimy bases, sections of the panel could warp or lift, thereby producing irregular light and poor heat passage.

In decor uses such as stone tops or bent shelves, bad contact frequently results in noticeable bright patches or shaded zones, and pliable LED sheets with managed bend limits lessen this danger on bases that lack perfect flatness.

Improper Adhesive and Fixing Methods

Folks often grab standard double-sided tape for ease, yet it can give way amid warmth or moisture, so over time, panels might lift, move, or droop, above all in upright placements.

Raymates LED sheets work with top-quality glues and attachment tools, which aid in holding firm contact for the long haul and cut down on refitting efforts.

Flexible Mounting Design of LENSED LED Sheet

For jobs with bends, angles, or intricate forms, LENSED LED SHEET provides superior fitting ability, as its bendable build enables neat placement along borders and odd arrangements without forming tension spots.

Thus, it fits nicely for cabinet displays, beauty counters, and building highlights where looks count as much as dependability.

What Happens When Heat Management Is Overlooked During Installation?

Warmth stays out of sight most times, but it directly sways LED durability and hue steadiness, and many LED panels quit not from electric overload, but because warmth lacks an exit path. Overlooking warmth control in setup brings steady light drop and hue unevenness.

Heat Buildup From Enclosed Installation

Placing LED panels within closed boxes or snugly shut areas locks in warmth, even though low-power panels create heat over long work times.

In the end, captured warmth hastens light output decline and softens solder links, which explains why certain panels seem okay initially but dim unevenly following months of service.

Lack of Ventilation and Aluminum Support

Lacking air flow spaces or aluminum bases keeps warmth pooled beneath the panel, and this poses extra risk for nonstop lighting in hotels, store networks, or promo lightboxes.

Adding aluminum sheets or channels boosts warmth shift and holds LED chips in a secure temp zone.

Low Heat Density Design of Raymates LED Sheets

Raymates LED sheets feature even LED placement and moderated power levels, which curb focused warmth buildup and back longer runtime.

Both MATRIX LED SHEET and LENSED LED SHEET suit extended business hours when set up with good air circulation and base backing.

Why Do Cutting and Connection Errors Cause Sudden Panel Failures?

Slicing and linking might look straightforward, but tiny slip-ups in these areas regularly spark abrupt breakdowns that prove hard to pinpoint. Accuracy counts a lot, especially during on-site tailoring of panels.

Cutting Outside Marked Sections

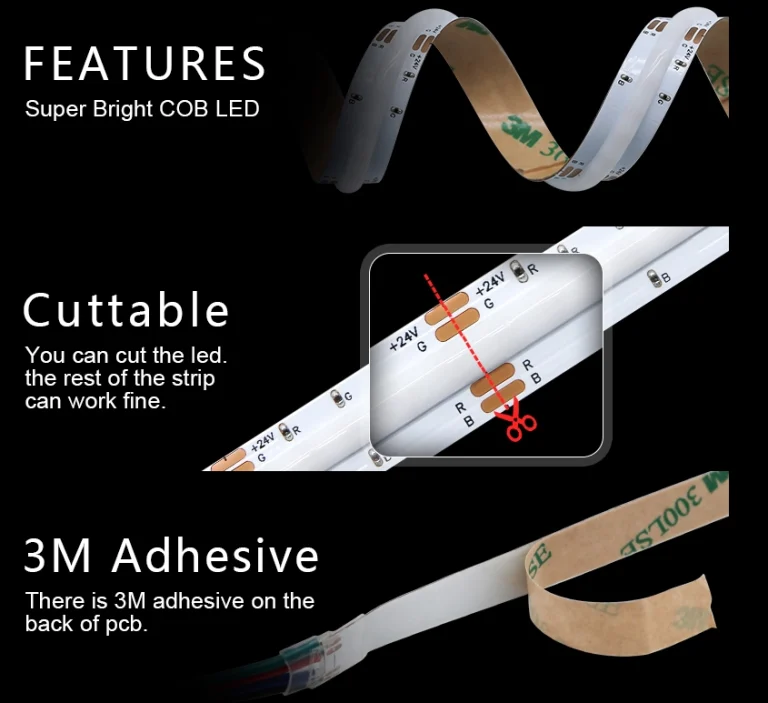

LED sheets include set slicing spots, and slicing beyond those zones can snap circuits or bare conductive lines, resulting in shorts or inactive parts. Certain cheaper panels miss obvious slicing markers, which raises setup dangers.

Unreliable Soldering and Connector Use

Weak soldering creates shaky joins that break down under shakes or warmth, while loose fittings also trigger on-off flickering that complicates fixes. Employing suitable fittings and neat solder spots remains key for firm output.

Precision Cutting Structure in MATRIX LED Sheet

MATRIX LED SHEET includes evident slicing paths and block-based setup, permitting secure tailoring without harming inner wiring, and this cuts field slip-ups while quickening assembly for major jobs.

How Can Choosing the Wrong LED Panel for the Application Ruin the Result?

Flawless setup cannot salvage a poor product pick, since varied uses require distinct light patterns, spread, and builds. Grasping these variances stops letdowns post-setup.

Using Standard Panels for High-End Backlighting

Basic LED panels might handle simple illumination, but they usually lag in upscale displays, as irregular spread, dim borders, or clear dots can spoil the sight. Upscale store and guest projects call for uniform brightness and even light coverage.

Mismatch Between Light Distribution and Surface Material

Stone, glass, and acrylic faces respond variably to light, so absent the proper LED build, shades or hue changes emerge.

Raymates crafts LED sheets aimed at backlighting tasks like onyx stone, marble tops, and showcase lightboxes.

Application-Focused Selection Between Lensed and Matrix LED Sheets

LENSED LED SHEET suits spots needing targeted light handling and bendability.

MATRIX LED SHEET excels in broad, even backlighting zones with firm power sharing. Picking the fitting build upfront spares time, expense, and hassle down the line.

FAQ

Q1: How long do Raymates LED sheets typically last with proper installation?

A: When you match power correctly, secure mounting well, and handle heat right, Raymates LED sheets hold up to 50,000 hours of steady work, fitting for ongoing business needs.

Q2: Can Raymates LED sheets be customized for specific project sizes?

A: Yes, Raymates offers tailored sizing, voltage picks, and OEM/ODM options to fit various project demands, all while ensuring safe and smooth setup.

Q3: Which LED sheet is better for curved or irregular surfaces?

A: LENSED LED SHEET gets the nod for bent or tricky layouts thanks to its pliable form, whereas MATRIX LED SHEET fits larger flat backlighting spots.