LED sheets light up spaces with awesome brightness, but keeping them on 24/7 needs smart heat and power management. From cooling tricks to steady voltage, knowing these basics keeps them shining safely. This guide dives into how tough designs—like those from RAYMATES—use cool materials and tech to stay reliable for heavy-duty use.

Key Electrical and Thermal Characteristics of LED Sheets

LED sheets are built to glow bright and save energy. But running them non-stop depends on a few key things. These include how much power they pull, how they handle voltage, and how they deal with heat. Most LED sheets use low-voltage DC power—usually 12V or 24V. They’ve got resistors or drivers to keep energy flowing smoothly.

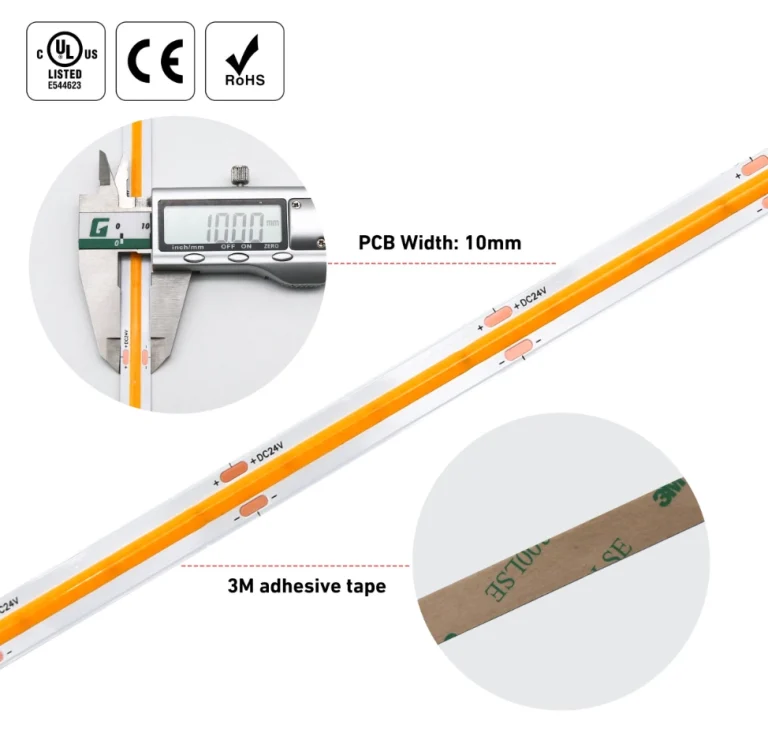

Flexible LED Sheet products are thin, bendy boards packed with LED chips in a grid. This setup spreads light evenly over big areas. It’s super flexible but needs good heat control. Even low-power LEDs make some heat when left on all day. Without cooling, that heat can mess up the insides.

Continuous Operation and Its Impact on LED Lifespan

Running LED sheets 24/7 puts stress on their diodes and circuits. LEDs can last a super long time—often 50,000 hours or more. But that’s only if conditions are perfect. Going too hot or using wrong voltages can dim them faster or change their colors.

COB LED Sheet tech crams tons of LED chips onto one board for extra brightness in a small space. But this tight setup needs strong cooling to keep working well during long runs.

Differences Between Consumer-Grade and Industrial-Grade LED Sheets

Not all LED sheets are the same. Cheap consumer ones focus on low cost over toughness. They might not have good heat sinks or protective layers for all-day use. But industrial-grade ones, like RAYMATES’ stuff, use better materials, stronger connections, and built-in cooling paths.

LED Luminous Sheet products give off tons of light and let you pick color temps for things like stores or buildings. These specs make them great for places needing non-stop light.

Evaluating the Safety Aspects of 24/7 LED Sheet Usage

Heat Generation and Thermal Management in Long-Term Operation

Heat’s the biggest worry for round-the-clock use. Even super-efficient LEDs turn some power into heat. Without stuff like aluminum backs or extra heat sinks, this can wreck insulation or start fires.

Hybrid LED Sheet mixes edge-lit and backlit tech for better light spread and efficiency. These often have fancy cooling paths to stop overheating during long use.

Fire Risk and Electrical Safety Considerations

Running non-stop can up the chance of electrical problems from worn-out parts or bad connections. Overloaded wires or sloppy setups might spark or catch fire. Always check that wiring follows safety rules and parts are made for constant use.

Importance of Power Supply Stability and Surge Protection

Power ups and downs can hurt LED sheets big time. A steady power supply with surge protection keeps voltage even. This stops damage from spikes or dips that could wear out parts faster.

Performance Degradation Over Time

Lumen Maintenance and Brightness Consistency in Extended Use

All LEDs get dimmer over time—it’s called lumen depreciation. How fast this happens depends on heat, power flow, and where they’re used.

Projection LED Sheet products are made for backlighting signs where steady light is a must. Their design keeps brightness even for a long time, perfect when dimming isn’t an option.

Effects of Prolonged Operation on Color Rendering Index (CRI)

Long use can mess with CRI—how well lights show true colors compared to sunlight. Lower CRI can make colors look off in stores or TV setups where accurate hues matter.

Material Fatigue in Flexible Substrates and Adhesives

In bendy LED sheets, the glue holding LEDs to the board can wear out from constant heat changes. This might cause peeling or weak spots, making the sheet less reliable.

RAYMATES LED Sheets: Engineered for Continuous Use

For 24/7 lighting that doesn’t quit, RAYMATES has you covered. Their products are built tough for hard-core settings—from fancy building designs to factory floors.

RAYMATES focuses on sturdy engineering. They use high-conductivity boards and smart chips that adjust heat on the fly. Every detail is about keeping things bright and safe for constant use. Their lineup mixes function with style—great when looks matter as much as performance.

Advanced Heat Dissipation Technologies in RAYMATES LED Sheets

RAYMATES uses layered boards and heat-conducting glue to pull heat away from delicate LEDs. Some models have tiny holes for airflow without letting water in. This keeps high-density sheets cool, even in tight spots like behind panels or in walls with no air.

Quality Control Standards Ensuring 24/7 Reliability

Every RAYMATES product gets hardcore testing, like running them for thousands of hours at max power. This proves they’ll hold up in real life, not just on paper. Their quality checks beat standard rules, so you know they’re built to last.

Recommended RAYMATES LED Sheet Models for Continuous Operation

High-Density Flexible LED Sheets for Commercial Applications

For store displays or hotel vibes needing smooth light over weird shapes, the Flexible COB LED Sheet rocks. Its packed diodes cut shadows, and the bendy base fits curves without breaking.

Waterproof and Dustproof Variants for Industrial Environments

In rough spots like factories or outdoor signs, RAYMATES’ IP-rated sheets block dust and water. They keep shining bright even in tough conditions.

Customizable Voltage Options Supporting Extended Runtime

RAYMATES offers 12V setups for mobile uses or 24V ones for big projects. These match your runtime needs without wasting power.

Best Practices When Using LED Sheets Continuously

Installation Guidelines to Maximize Airflow and Cooling Efficiency

Stick sheets on heat-friendly surfaces like aluminum panels. Don’t trap them in tight spaces unless you’ve got fans or vents. Passive airflow might not cut it in hot weather or stuffy rooms.

Monitoring Systems for Temperature and Voltage Regulation

Add heat sensors near hot spots in your setup. Use smart controllers to check temps in real time. This catches problems before they get big.

Scheduled Maintenance to Extend Operational Life

LEDs don’t need much upkeep, but regular checks help. Look for rusty connectors, clean off dust that blocks cooling, and test voltage every few months.

Industry Applications That Benefit from 24/7 LED Sheet Use

Architectural Lighting in Public Infrastructure Projects

Airports and subways love edge-lit sheets for even light across big panels. They run non-stop without flickering thanks to solid drivers. Edge-Lit LED Sheet uses side LEDs with a light guide panel for smooth light spread.

Retail Display Lighting Requiring Constant Illumination

Luxury store displays need steady light to show off products. These sheets keep colors true even after hours of use in changing room temps.

Backlighting Solutions in Broadcast, Stage, and Exhibition Settings

Event displays or stage backgrounds run all day. They need thin, powerful sheets that stay bright without getting hot—perfect for RAYMATES’ designs.

FAQ

Q: Can all types of LED sheets be used continuously?

No. Only industrial-grade ones with good heat control should run 24/7. Consumer-grade ones might wear out fast.

Q: How do I prevent overheating during continuous operation?

Make sure air flows around the setup. Use heat-conducting mounts and pick models with cool tech for heat control.

Q: Will running an LED sheet constantly affect its brightness?

Yeah, brightness fades over time due to diode wear. High-quality models like RAYMATES’ slow this down a lot.