Picking the right LED sheet can make or break your lighting project. Whether you’re lighting up a retail display or adding glow to a hotel lobby, these thin, flexible panels pack a punch in efficiency and style. At Raymates, we’ve been crafting LED solutions since 2009, starting with a small team and growing into a global player with factories running under ISO9001 standards. In this guide, we’ll walk through the main things to consider, drawing from real-world installs and our own product line to help you nail your choice.

What Are the Essential Material Characteristics?

When you’re hunting for an LED sheet, the materials set the foundation for how it performs day in and day out. Think about where it’ll go—curved walls, tight spaces, or heavy-use areas. The right build keeps things running smooth without headaches later.

Flexible Substrate Options

Raymates’ LED sheets use flexible PCBs that bend easily around corners, like in a bar counter wrap we did last year. This lets you shape them to fit odd spots without cracking.

Ultra-Thin Lightweight Design

Our sheets come in at just 1-3mm thick, making them a breeze to ship and mount. One client saved big on transport costs for a large hotel project, where weight mattered for ceiling installs.

Durable PCB-Based Construction with Raymates Recommendations

We back our sheets with aluminum for heat control, extending life to over 50,000 hours. Pick our Matrix LED Sheet for tough spots; it’s built to handle daily wear in busy stores.

It’s not just about bending or thinness, though. These traits tie directly into how the sheet fits your specific setup, from a home accent to commercial shelves.

How Does Application Influence LED Sheet Selection?

Your project’s end use drives what LED sheet works best. A backlit sign needs different specs than kitchen under-cabinet lights. We’ve seen clients mix it up wrong and end up with dim spots or color shifts.

Backlighting for Displays

For ad boxes or menu boards, go with even diffusion. Our Lensed LED Sheet spreads light without hot spots, perfect for a cosmetics counter we lit up in a mall—colors popped just right.

Decorative Lighting Solutions

In homes or events, warmth matters. Raymates sheets offer tunable whites from 2700K to 6500K, like in a wedding venue where we created soft glows along walls.

Commercial Shelf Illumination Using Raymates Products

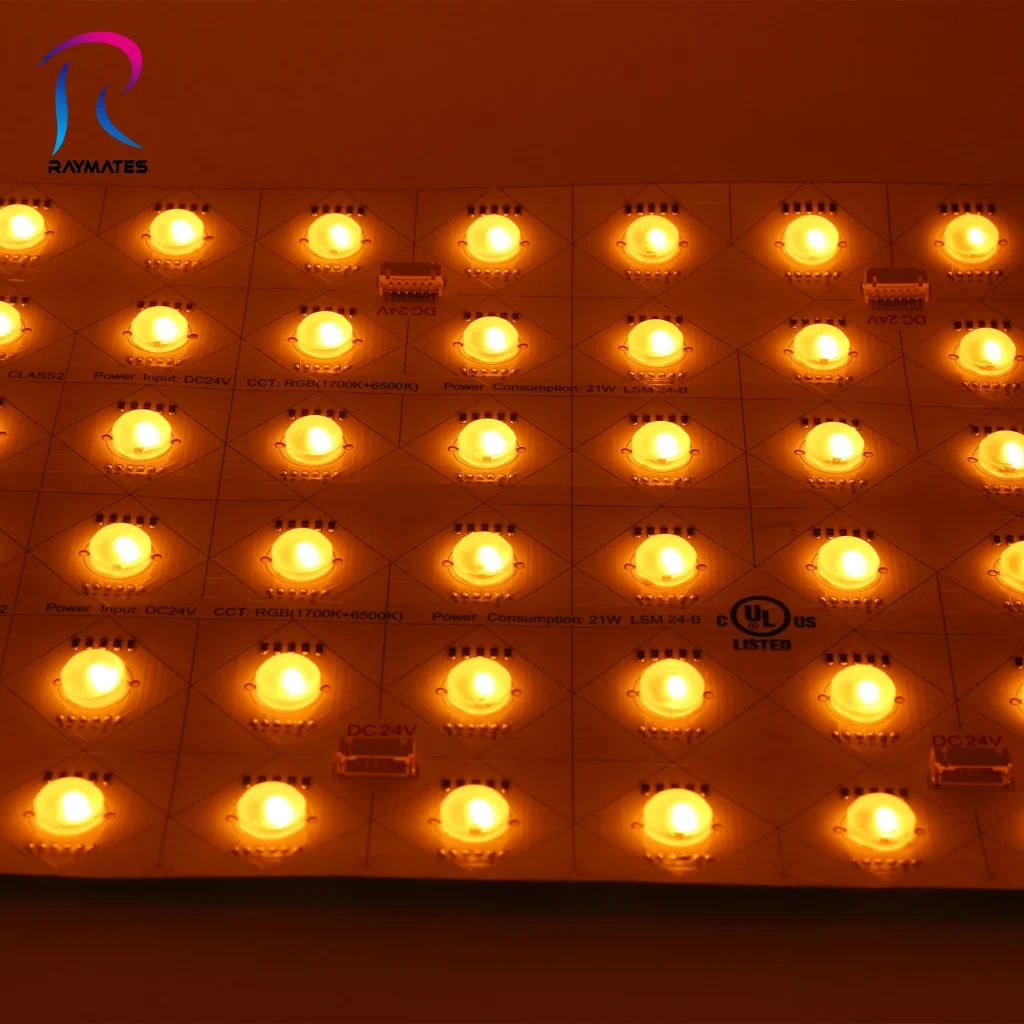

Stores need bright, true colors. Our Matrix series hits CRI over 90, highlighting products in a clothing shop install—sales jumped because items looked better under the light.

Beyond the basics, tech specs like color accuracy and control options can elevate a good setup to great. Let’s dig into those next.

What Technology Features Matter Most?

Tech in LED sheets isn’t fluff; it solves real issues like uneven brightness or lack of control. From our factory upgrades in 2013 with SONY SMT machines, we’ve focused on packing more smarts into each panel.

High CRI Uniformity

Aim for CRI 90 or higher to make colors true. Raymates sheets deliver this with tight LED spacing—about 20mm—eliminating shadows in art galleries we’ve outfitted.

Programmable Dimming Capabilities

Control brightness zones for flexibility. Our programmable options let you dim parts of a sheet, handy in exhibitions where one area needs spotlighting while others fade back.

COB Integration in Raymates LED Sheets

Chip-on-Board tech boosts efficiency. In our Lensed line, COB means brighter output with less power, as seen in a bridge lighting job using similar high-voltage strips—clean, even glow over 50 meters.

Customization isn’t a luxury; it’s often what makes a project feasible. We’ve helped startups with small runs avoid big mold costs through smart tweaks.

Why Is Customization Crucial for Projects?

Off-the-shelf might work for simple jobs, but custom fits save time and money long-term. Think about voltage mismatches or odd shapes—we’ve fixed those for clients more times than I can count.

Cuttable Segment Designs

Sheets with marked cuts—like every 1, 3, or 6 LEDs—cut waste. Raymates lets you trim precisely, as in a furniture edge job where we avoided scraps entirely.

Custom Voltage Compatibility

Match your setup: 5V, 12V, up to 48V low-voltage options. We tailored a 24V sheet for a client’s display, dodging extra driver hassles.

Tailored Shapes from Raymates Lensed LED Sheet

Irregular forms? No problem. Our Lensed series molds to logos or curves, like a custom panel for a hotel corridor that hugged the architecture perfectly.

Quality isn’t just talk; certifications back it up. They open doors to markets and give peace of mind on safety.

How Do Certifications Impact Quality Assurance?

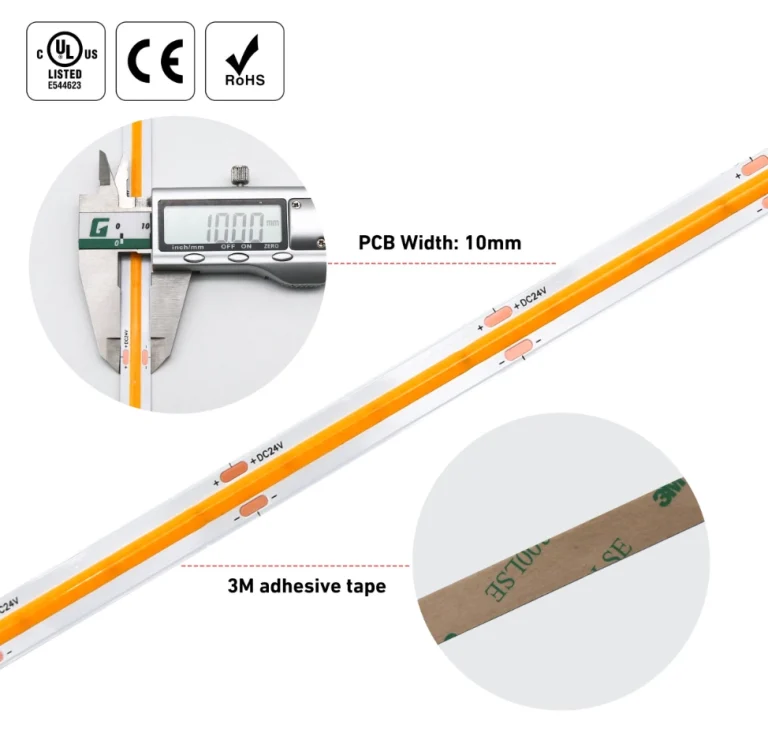

Certs prove a sheet meets global rules, from safety to eco-friendliness. Since getting UL and CE in 2015, Raymates has shipped to over 30 countries without compliance snags.

UL and CE Compliance

These ensure fire safety and performance. Our sheets pass rigorous tests, letting clients install in North America or Europe without worries.

RoHS Environmental Standards

No nasty stuff like mercury. Raymates complies fully, appealing to green projects—like a park install where UV-free light was key.

Global Market Certifications for Raymates Matrix LED Sheet

With ETL, TUV, and more, our Matrix line fits anywhere. A Saudi client used it for outdoor signs, trusting the certs for harsh weather.

Installs can trip you up if you’re not ready. We’ve guided folks through curves and power puzzles since our sales team expanded in 2023.

What Installation Challenges Should You Anticipate?

Jumping into install without planning? Common pitfalls like rebounding on bends or wrong power can stall things. But with the right sheet, it’s straightforward.

Curved Surface Fixation

Use strong tape like 3M 9448A. Raymates sheets stick firm on arcs, as in a display cabinet we did—no popping off after months.

Power Supply Matching

Get the volts right to avoid flickers. We match drivers to our sheets, simplifying setups for a food plant client in humid spots.

Easy Plug-and-Play with Raymates Solutions

Connectors make it quick. Our plug-ins cut labor time, like in a warehouse where install took half the expected hours.

Finally, weigh the costs against what you get back. Cheap sheets fail fast; smart picks pay off.

How to Assess Cost-Effectiveness and Reliability?

Upfront price is one thing, but factor in energy bills and downtime. Raymates doubled sales in 2023 by delivering value that lasts.

Energy Efficiency Savings

Low power draw—our sheets sip electricity, cutting costs 30-50% in a retail chain we supplied.

Long Lifespan Ratings

50,000 hours minimum, L70 standard. Clients report years of use without fade, like in a bridge project still shining bright.

Value-Driven Options like Raymates LED Sheets

Balance features and price. Our lines offer high-end perks without premium tags, helping startups scale without breaking the bank.

Wrapping up, choosing an LED sheet boils down to matching materials, apps, and tech to your needs. At Raymates, we’re here with custom solutions and solid support. Check our site for more on the Lensed and Matrix series.

FAQs

Q1: What makes Raymates LED sheets stand out from competitors?

A: Our focus on flexible, cuttable designs with high CRI and global certs sets us apart. Plus, we’ve got a track record since 2009, with custom options that fit tight budgets.

Q2: Can I use LED sheets in wet areas?

A: Yes, but check IP ratings. Our Matrix series hits IP65 or better for humid spots like kitchens or outdoors—always test first.

Q3: How do I get started with a custom LED sheet order?

A: Drop us an email with your specs. We’ll quote fast, often within a day, and guide you through from design to delivery.