LED sheet lights have moved beyond being a specialized item just for lightboxes or display cases. By 2026, they serve as a preferred choice for designers, builders, and purchasers seeking clear illumination, adaptable arrangements, and dependable operation in varied setups. From beauty shop fixtures to lodging spaces and rock illumination, LED sheet lighting appears frequently in spots where standard strips and stiff boards prove inadequate.

This overview explains precisely what LED sheet lights involve, the reasons behind rising interest, and how Raymates aids expert endeavors with trustworthy LED sheet options, including Lensed LED Sheet and Matrix LED Sheet setups.

What Are LED Sheet Lights And Why Are They Gaining Popularity in 2026?

The growth of LED sheet lights links directly to shifts in business design and illumination practices. Current undertakings demand slimmer builds, smoother light areas, and simpler tailoring, particularly in upscale stores and building features.

Prior to examining practical uses and selection advice, it proves helpful to grasp what sets LED sheet lights apart from other LED types.

Definition And Core Structure Of LED Sheet Lights

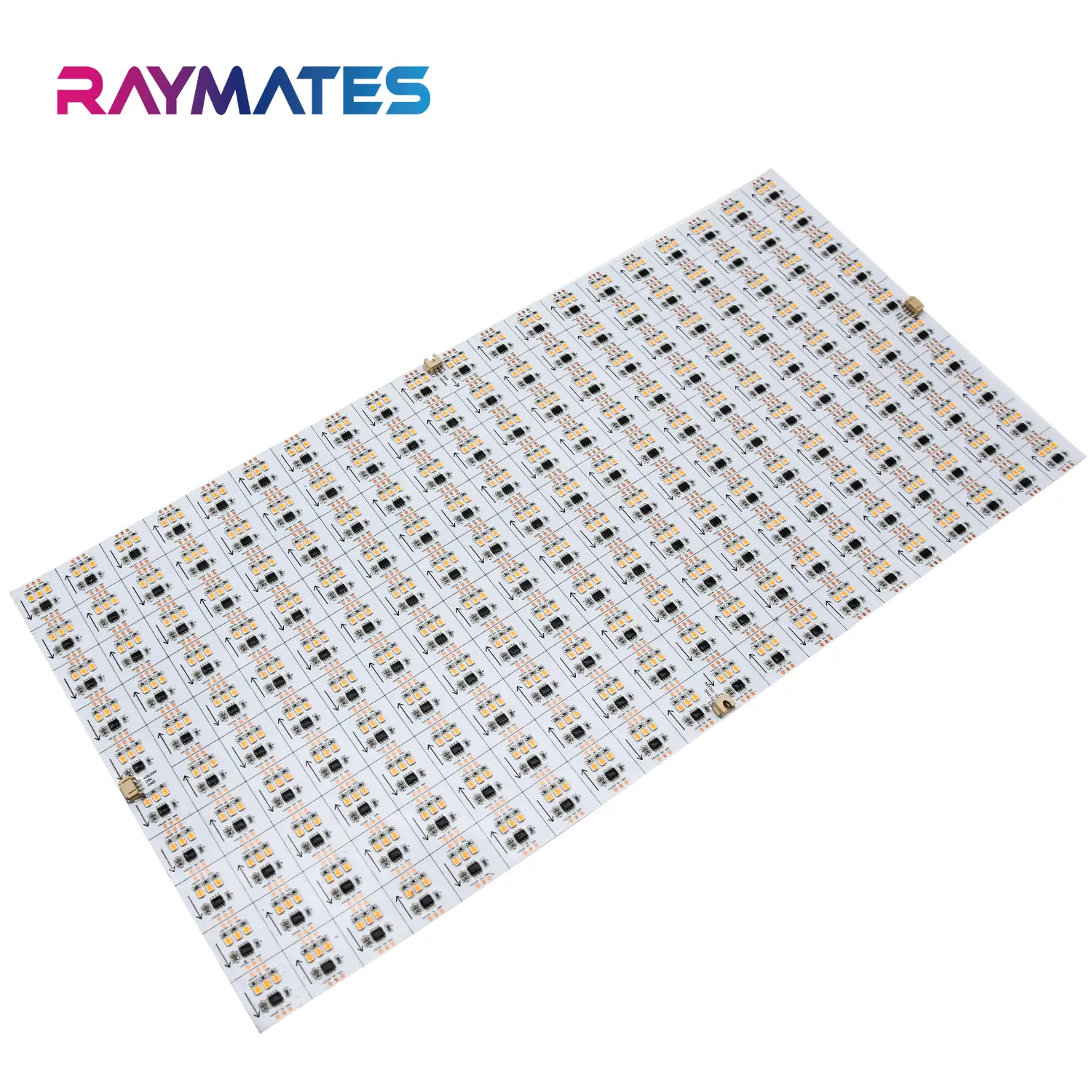

LED sheet lights, sometimes known as LED light sheets or LED sheet panels, consist of flat illumination boards featuring LEDs positioned at regular intervals on a pliable or somewhat firm base. In contrast to LED strips that follow linear paths, LED sheets distribute light over an area, yielding steady and balanced glow.

Typically, LED sheets employ PCB or flexible PCB bases, and they include marked cut spots, so users can resize or form the sheet to fit actual project measures. Consequently, they suit backlighting tasks where consistent brightness outweighs focused beams.

Raymates LED sheet items aim for reliable emission, distinct cutting lines, and uniform LED placement, which aids in minimizing dim patches and irregular borders in completed setups.

Key Advantages Over Traditional LED Strips And Panels

When set against regular LED strips, LED sheet lights eliminate frequent spot patterns and lessen the reliance on additional spreading layers. As a result, light flows naturally over the board, conserving area and assembly efforts.

Against fixed LED panels, LED sheets remain slimmer, weigh less, and adapt more readily to bent or uneven forms. In cases involving marble, onyx, glass, or slim enclosures, this adaptability turns into a practical benefit rather than a mere trait.

Within numerous undertakings, LED sheet lights occupy a balanced position, delivering finer light standards than strips while granting greater arrangement options than set panels.

Common Applications In Commercial And Architectural Projects

LED sheet lights find broad use in beauty fixtures, store racks, hotel lounges, front desks, and ornamental wall elements. Furthermore, they function effectively in illuminated stone, promo lightboxes, and showcase units where pure, level light holds importance.

Raymates LED sheets often get picked for luxury hotel setups, named store exhibits, and tailored business spaces that require both striking visuals and extended durability.

How Do LED Sheet Lights Improve Lighting Quality And Design Flexibility?

Effective lighting extends past mere intensity. It concerns the appearance of light, its distribution, and its harmony with surrounding forms. LED sheet lights handle these elements in manners that numerous other illumination forms cannot achieve. Grasping these gains assists project purchasers in supporting their selection past cost considerations alone.

Uniform Light Output For Seamless Backlighting

A primary asset of LED sheet lights lies in their balanced emission. LEDs sit at managed distances, thereby preventing bright clusters and shade streaks.

Such uniformity counts heavily in tasks like beauty showcases or rock tops, since irregular light swiftly lowers aesthetic value. Raymates LED sheets incorporate exact LED intervals and firm current regulation, ensuring the glow remains level over the entire area. In ventures where looks shape brand perception, this evenness frequently serves as the key influence.

Ultra-Thin And Cuttable Design For Custom Shapes

Nearly all LED sheet lights measure just several millimeters in depth, so they conceal easily behind boards, within fixtures, or beneath rock layers. Their resizable build lets fitters adjust sheets in place without harming the wiring, provided they adhere to cut indicators.

Raymates LED sheets accommodate sensible cutting schemes and sectional patterns, which cut down on resource loss and ease bespoke constructions. For arched lounges, angle connections, or odd enclosure forms, this pliability preserves both effort and workforce.

Stable Performance With High CRI And Long Lifespan

Illumination standard involves not just strength but also hue fidelity. Elevated CRI sources aid items, finishes, and substances in appearing nearer to their true shades.

Raymates LED sheet lights target business-level operation, providing elevated CRI choices and prolonged expected durations. Paired with minimal light reduction, this renders them fitting for tasks where upkeep entry proves scarce or interruptions carry expense.

What Makes Raymates LED Sheet Solutions Suitable For Professional Projects?

Plenty of LED sheet goods appear alike in descriptions. Distinctions emerge post-fitting, amid extended operation, or when approvals and supply times hold weight. Raymates emphasizes consistent production, worldwide standards, and venture-specific aid over temporary costs.

ISO9001 Manufacturing And Full Quality Inspection

Raymates runs via the ISO9001 quality framework, encompassing base choices, fabrication, and end checks. Each LED sheet undergoes review prior to dispatch, thereby lowering chances of faulty LEDs, power inconsistencies, or irregular yields. This method assists project purchasers in dodging refits, location holdups, and swap fees down the line.

Global Certifications For International Markets

Raymates LED goods possess approvals like UL, ETL, CE, RoHS, and TUV. Such approvals typically prove necessary for ventures in North America, Europe, and the Middle East.

For purchasers operating over boundaries, approved LED sheet lights ease sanction hurdles and streamline adherence amid project evaluations.

Flexible Voltage, Power, And Size Customization

Varied tasks call for distinct power amounts and voltage setups. Raymates supplies both reduced-voltage and elevated-voltage variants, plus power tailoring to align with emission requirements.

Board depths, sheet configurations, and linking approaches can likewise shift, thereby backing OEM and ODM partnerships for marked or particular ventures.

Which Raymates LED Sheet Product Fits Different Project Needs?

Picking the proper LED sheet avoids seeking the priciest choice. Instead, it centers on aligning light traits with the task. Raymates delivers two main LED sheet answers that handle most business backlighting demands.

Lensed LED Sheet For Focused And Controlled Illumination

The Lensed LED Sheet employs optical covers atop each LED to manage light paths more effectively. This setup boosts emission productivity and curbs light waste in deeper placements.

It suits ventures requiring firmer output or directed spread, such as dense rock illumination, profound lightboxes, or zones where the source rests distant from the face.

Matrix LED Sheet For Large-Area And Modular Backlighting

The Matrix LED Sheet displays a grid-based arrangement that enables simple growth over broad areas. It fits expansive boards, extended fixtures, and sectional exhibit frameworks.

The grid form permits neat cabling and level emission over linked parts, thereby easing enlargement without evident light variances.

Typical Use Cases For Each LED Sheet Type

Lensed LED Sheets commonly appear in top-tier exhibits, thick substances, and spots demanding managed intensity. Matrix LED Sheets typically serve store racks, lounge tops, and building boards where vast, level expanses carry weight. Opting for the fitting kind at the outset aids in steering clear of excess planning or weak results later in the venture.

How Should Buyers Choose The Right LED Sheet Lights In 2026?

Procuring LED sheet lights goes beyond mere specifications. It encompasses grasping the task setting, fitting approach, and enduring hopes. A straightforward picking method lowers hazards and betters end outcomes.

Matching LED Sheet Type With Application Scenarios

Illuminated rock, glass boards, and beauty exhibits generally gain from greater evenness and directed intensity. Ornamental fixtures and racks might prioritize arrangement pliability and area span. Recognizing the chief aim of the illumination aids in swiftly pinpointing the suitable LED sheet build.

Key Technical Parameters To Check Before Ordering

Purchasers ought to verify voltage, power concentration, CRI, cut spots, and linking ways ahead of orders. Alignment with drivers and regulators holds relevance too, particularly for fading or area regulation. Raymates backs technical talks at this point, which aids in preventing mismatched parts.

Working With OEM And ODM Capabilities For Custom Projects

For marked ventures or ongoing fits, OEM and ODM offerings grant finer command over item dimensions, tags, and operation. Raymates backs both forms, delivering tailored LED sheet answers grounded in genuine task demands instead of set list goods.

FAQ

Q1: What is the main difference between LED sheet lights and LED strips?

A: LED sheet lights distribute light over a surface, whereas LED strips release light along lines. Sheets yield more balanced glow and curb spot patterns, particularly for backlighting.

Q2: Are Raymates LED sheet lights suitable for international projects?

A: Yes. Raymates LED sheet products bear approvals such as UL, CE, and RoHS, rendering them apt for ventures in North America, Europe, and further key regions.

Q3: Can LED sheet lights be customized for unique project sizes?

A: Yes. Raymates endorses resizable builds and OEM/ODM services, permitting LED sheets to adapt for bespoke forms, power tiers, and configurations.