Every top-notch architectural lighting option follows a lengthy journey from initial idea to final item. A Matrix LED Sheet might appear straightforward when fitted in place, yet its creation demands thoughtful planning, smart material picks, and tight production oversight. At Raymates, this process is shaped by years of hands-on experience in LED manufacturing and real feedback from global projects.

This article walks through how a Matrix LED Sheet is created, step by step, and why the MATRIX LED SHEET has become a trusted option for backlighting, decorative lighting, and premium display applications.

What Is A Matrix LED Sheet And Why Does It Matter?

Before diving into production details, it helps to understand what makes a Matrix LED Sheet different from other lighting formats. This foundation explains why it is widely used in both commercial and high-end interior projects.

Matrix LED Sheet Definition And Function

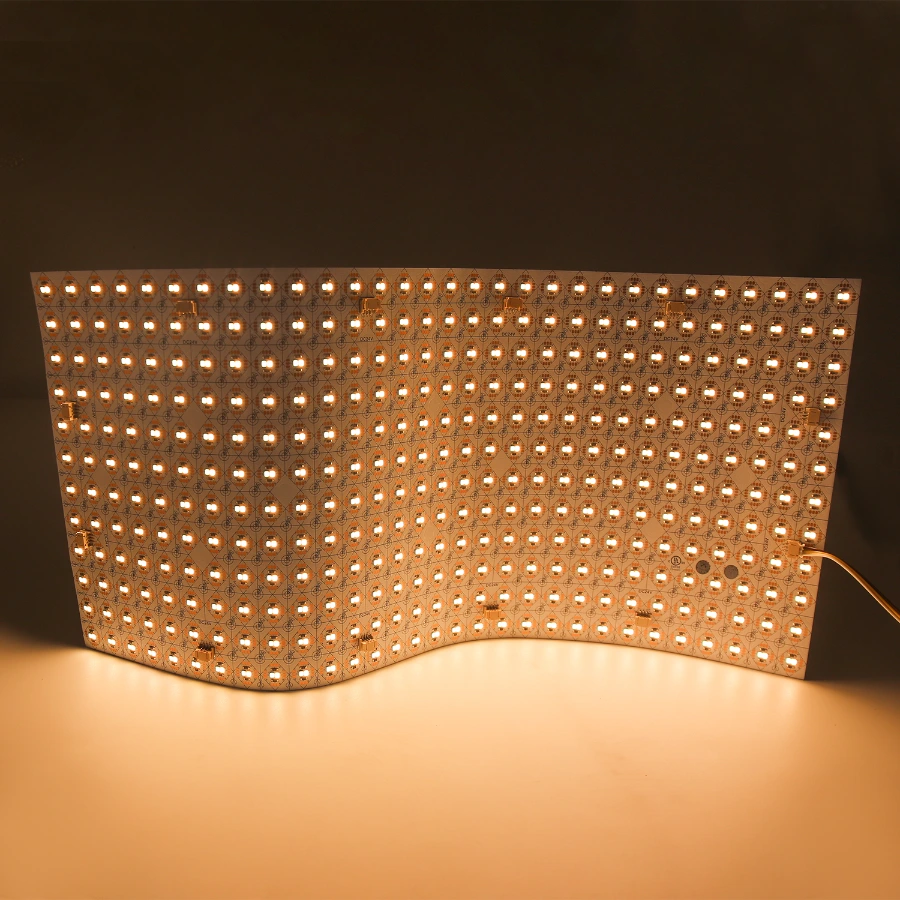

A Matrix LED Sheet is a flat, modular lighting panel made of evenly spaced LED points mounted on a flexible or semi-flexible circuit. Unlike LED strips that follow a single line, the matrix layout spreads light across a surface. This structure delivers smooth brightness over large areas without obvious hotspots.

Raymates’ MATRIX LED SHEET is designed for backlighting materials such as onyx, marble, acrylic panels, and light boxes. The sheet can be cut along marked points, making it easy to fit custom shapes while keeping stable performance.

Advantages Of MATRIX LED SHEET In Lighting

The matrix build offers various useful perks. Light spread remains uniform, borders stay neat, and the overall look feels even when seen nearby. When using premium LEDs and precise gaps, dim areas and shaded parts drop off significantly.

Another strong point is flexibility. The MATRIX LED SHEET can bend gently around curves or irregular surfaces, which is useful for counters, columns, and custom display furniture. For installers and designers, this saves time and reduces on-site adjustments.

Market Need For High-Performance LED Sheets

Modern lighting projects demand more than brightness. Hotels, retail brands, and display designers want lighting that looks soft, stable, and reliable over time. Traditional rigid panels often limit design freedom, while loose LED strips struggle with uniformity.

Matrix LED Sheets sit in the middle. They offer design freedom without losing light quality. According to recent industry reports, the global LED lighting market was valued at USD 88.17 billion in 2024 and is projected to grow at a CAGR of 7.8% from 2025 to 2030, reaching USD 134.71 billion. This balance explains why Raymates has seen growing demand for MATRIX LED SHEET across cosmetics counters, luxury interiors, and branded display spaces.

How Does Raymates Turn An Idea Into A Real Product?

Turning a lighting concept into a sellable product takes more than sketches. Each step needs to connect design goals with real manufacturing conditions.

Ideation And Design Process Overview

Every product starts with a clear use case. Raymates designs Matrix LED Sheets around actual installation scenes, such as stone backlighting or shelf lighting in retail stores. Engineers define target brightness, voltage options, cutting points, and board size early on.

Instead of chasing extreme specs, the focus stays on stable output and easy handling. This approach helps avoid over-engineering and keeps products practical for daily use.

Engineering And Prototyping Stages

Once the layout is confirmed, prototypes are built using selected LEDs and circuit materials. Spacing between LEDs is tested to find the right balance between brightness and visual comfort. Too close can raise heat, too far creates uneven light.

At this stage, Raymates also checks bending behavior, solder strength, and cutting accuracy. The goal is a sheet that performs well not only in the lab but also on real job sites.

Testing And Quality Assurance Practices

Before moving to mass production, samples go through electrical tests, aging tests, and visual inspections. Voltage stability and current flow are checked under long operating hours.

Raymates follows ISO9001 quality management standards, and every batch is inspected before shipping. This strict process helps keep color consistency and brightness uniform across orders, which matters for large projects.

What Materials And Technologies Are Used In MATRIX LED SHEET?

Materials play a quiet but critical role in lighting quality. Even small changes in substrate or LED type can affect lifespan and visual output.

Core Materials And Their Properties

The MATRIX LED SHEET uses high-grade flexible PCB materials that balance thinness and strength. This structure allows bending without damaging solder points.

The LEDs selected offer high color accuracy and low lumen drop over time. For backlit stone or display panels, stable color temperature is essential, especially in warm white and natural white ranges.

LED Driver And Circuit Innovations

Stable lighting depends on more than LEDs alone. The circuit design supports consistent voltage distribution across the sheet, even after cutting. This reduces the risk of uneven brightness when custom shapes are needed.

Raymates designs its Matrix LED Sheets to work smoothly with common constant-voltage power supplies, which simplifies driver matching during installation.

Manufacturing Equipment And Precision

Up-to-date SMT gear and heat-solder lines place LEDs with sharp accuracy. Uniform gaps and tidy joints form the base for lasting dependability.

Cutting-edge check devices, like light spheres, aid in confirming glow yield and hue work before items exit the plant.

How Is MATRIX LED SHEET Manufactured At Scale?

Scaling up production is where many designs fail. A good concept must stay consistent when produced in large volumes.

Automated Production Line Setup

Raymates counts on auto SMT lines to manage hefty orders while holding caliber firm. Auto steps lessen worker slips and aid in keeping the same level from start to end. Making lines adjust to varied panel sizes and power types without delaying send-out times.

Quality Control Throughout Production

Quality checks are not limited to final inspection. Materials are tested before assembly, and in-process checks catch issues early. This layered control helps avoid batch problems such as color shifts or uneven brightness.

Every MATRIX LED SHEET is inspected before packing, which lowers the risk of defects reaching customers.

Packaging And Logistics Strategy

Because LED sheets are thin and flexible, packaging matters. Raymates uses protective materials to prevent bending damage and moisture exposure during transport.

With global shipping experience and partners like DHL, UPS, and FedEx, delivery stays fast and predictable for international customers.

Why Choose MATRIX LED SHEET For Your Lighting Project?

After understanding how it is made, the real question becomes how the product performs in daily use.

Performance Benefits For End Users

MATRIX LED SHEET delivers smooth, comfortable light that works well behind stone, glass, and acrylic. High CRI options help colors look natural, which is important for retail and hospitality spaces.

Long lifespan and low lumen decay mean less maintenance over time, a key factor for commercial installations.

Customization And Application Flexibility

Cuttable design, multiple voltage options, and flexible formats make the sheet suitable for both small displays and large decorative surfaces. From hotel bars to branded counters, designers gain more freedom without adding complexity.

The global architectural lighting market, closely aligned with premium backlighting and decorative applications, was estimated at USD 10,203.7 million in 2024 and is projected to reach USD 15,978.5 million by 2030, growing at a CAGR of 7.7% from 2025 to 2030. This steady expansion underscores the rising demand for flexible, high-uniformity solutions like the MATRIX LED SHEET in luxury interiors and commercial projects.

Raymates also supports OEM and ODM services, allowing partners to match lighting solutions with their own branding or project needs.

Raymates Support And Service Advantages

Beyond the product itself, Raymates offers technical guidance, installation support, and clear communication during ordering. Years of export experience and global certifications such as UL, CE, and RoHS make cooperation smoother for overseas buyers.

This combination of product quality and service mindset has helped Raymates build long-term partnerships across more than 30 countries.

FAQs

Q1: Where is MATRIX LED SHEET commonly used?

A: It is widely used for backlit stone, marble countertops, cosmetics counters, display light boxes, hotel interiors, and decorative panels where uniform light is required.

Q2: Can MATRIX LED SHEET be cut without affecting performance?

A: Yes. The sheet is designed with clear cutting points. When cut correctly, brightness and electrical stability remain consistent.

Q3: Does Raymates support custom Matrix LED Sheet projects?

A: Yes. Raymates provides OEM and ODM services, including size, voltage, and layout customization based on project requirements.