Keeping LED panels in good shape saves money in the long run, especially for shops, hotels, and any space that depends on steady lighting. When panels stay clean and well-treated, they last longer and run with fewer problems. This is true for many lighting products, but it is especially clear with flexible LED sheets such as the Lensed LED Sheet and Matrix LED Sheet from Raymates. These panels are built for long service, but like any lighting system, they work best when cared for the right way.

Why Proper LED Panel Care Matters for Long-Term Performance?

LED panels may look simple on the outside, but the small parts inside need a stable environment to stay bright. Poor care slowly reduces their life, which means more replacements and more labor costs. So it makes sense to look at how basic habits can help panels stay at a steady performance level for years.

LED Panel Lifespan Stability

LED sheets can run for tens of thousands of hours, but outside factors can shorten that life. Dust builds up faster than most people expect, especially in areas with a lot of foot traffic. Even a thin layer of dust can trap heat, and heat is one of the biggest reasons panels start to fade early.

Regular cleaning helps avoid overheating and keeps the surface smooth for better light spread. Moisture is also a common problem. Humidity can slowly affect the solder joints, and once oxidation starts, small connection problems follow. None of this happens overnight, but little by little it weakens the panel. Good care keeps these issues away for much longer.

Operational Cost Reduction

Better care also means fewer surprises. A panel that stays clean and cool works more steadily. Shops that use LED sheets for display shelves or backlit marble don’t want flickering or sudden dim areas. Once a panel becomes uneven, staff must stop work, replace parts, and sometimes re-install whole sections. These hidden costs add up. With regular care, panels continue to run smoothly without constant attention.

Risk Prevention in Daily Use

Many problems start because someone bends a panel too sharply or stacks heavy boxes on top during storage. Flexible LED sheets like Raymates products can curve nicely, but they still have limits. Too much force leaves invisible cracks in the tiny wires inside. Those cracks show up months later as dead lines or dark patches. Gentle handling, flat storage, and keeping them away from damp corners prevent almost all of these expensive accidents.

How to Clean and Maintain LED Panels the Right Way?

Cleaning LED panels is easy and cheap. You don’t need fancy tools — just the right gentle touch. Most damage actually comes from people using wrong cleaners or rubbing too hard.

Safe Cleaning Methods

A soft microfiber cloth is usually enough to wipe away dust. For sticky marks or fingerprints, a mild cleaner that is safe for electronics can help. It’s important not to spray liquid directly on the panel. Liquids that seep into the edges or the circuitry can cause slow damage. Cleaning lightly and steadily works better than a hard scrub. Even pressure and simple tools keep the panel surface bright without risk.

Regular Inspection Essentials

LED panels benefit from quick check-ups. A short inspection every now and then helps notice early signs of trouble. If a connector looks loose or a part feels warmer than usual, it may point to an issue in the power supply or airflow. Looking at brightness levels, corner shadows, or strange flickers is sometimes enough to catch problems early. This habit is useful in hotels, bars, or retail stores where lights run for many hours a day.

Proper Handling and Storage

Before panels are installed, they often spend days or weeks in storage. Good storage conditions protect the sensitive parts. Keeping the panels in anti-static bags is helpful, and storing them flat avoids unwanted bending. Humidity is also something to watch. Too much moisture over time can damage solder joints. So keeping panels in a dry space makes them last longer, even before they are used.

What Installation Practices Help Reduce Future Maintenance?

A good installation is one of the strongest ways to cut down future costs. Even a high-quality LED sheet can run into trouble if the installation is rushed or done with the wrong tools. Careful installation avoids many common issues that would otherwise appear later.

Correct Mounting Techniques

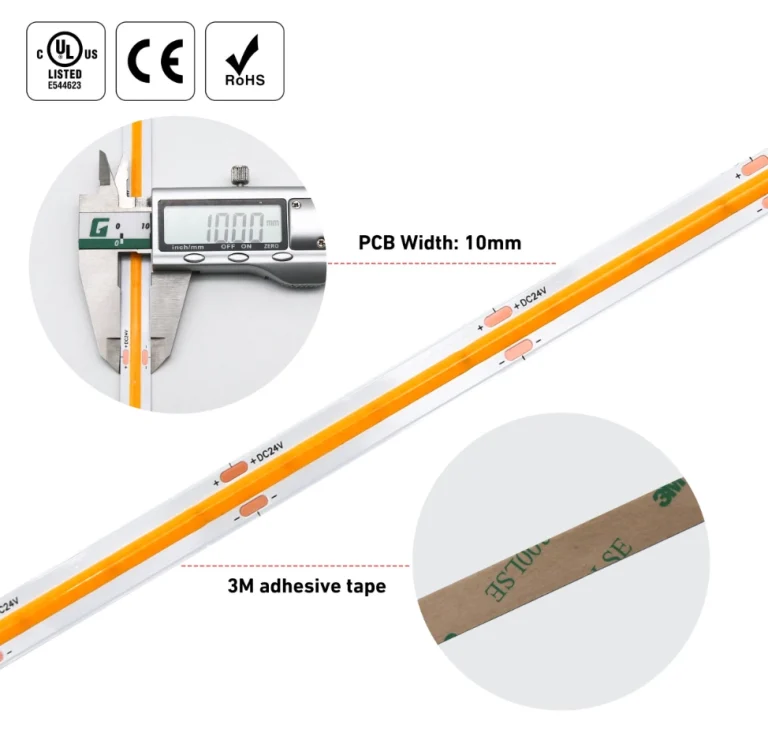

Flexible LED sheets stick best on clean, flat surfaces. Dust or rough textures can weaken the grip. If a surface is curved, using the right mounting clips or stronger adhesive helps the panel stay in place without lifting over time. A stable mount keeps the panel straight, which also improves lighting uniformity. When panels start to peel or shift, maintenance becomes more frequent, so getting the mounting right from the start is worth the time.

Matching the Right Power System

Voltage is a detail that cannot be ignored. LED sheets built for 12V or 24V systems must run with the correct drivers. Using the wrong power supply places stress on the LEDs. The damage may not show immediately, but brightness reduces faster and the panel wears out sooner. Using certified drivers with stable output helps avoid “hot spots” and early failures. In large projects like hotel corridors or display counters, the right power match is even more important because long runs increase the load.

Heat Management Practices

Heat is a quiet enemy for LED sheets. Good airflow keeps the temperature balanced and slows down aging. Some installations need aluminum channels or open back panels to help release heat. When LED sheets sit behind stone, glass, or acrylic, the heat has fewer ways to escape. So leaving a little spacing or using heat-friendly materials makes a difference. Panels that run cooler stay bright for a longer time and need fewer replacements.

Which Raymates LED Panels Offer Lower Maintenance Requirements?

Choosing the right LED panel also influences maintenance needs. Raymates has been producing LED lighting products since 2009 and has built its systems around stable performance, strict quality control, and long-term durability. Their Lensed LED Sheet and Matrix LED Sheet are two popular choices for projects that want both good lighting and low maintenance demand.

Lensed LED Sheet for High Uniformity

The Lensed LED Sheet is made to spread light smoothly, which helps with backlit designs where any dark spot becomes noticeable. Its layout and lens structure push light evenly across the surface. This panel bends easily around corners and can be cut at marked points, making installation simpler and reducing mistakes. It is used a lot in hotel bars, cosmetics counters, and marble backlighting because the bright and steady glow makes the space look more refined.

Matrix LED Sheet for Durable Performance

The Matrix LED Sheet focuses on steady brightness over long use. The LED spacing stays consistent across the sheet, giving a clean look even after years of operation. It handles heat well, which is important for large display walls or lightboxes that stay on for long hours. The durable layout keeps maintenance low because the lighting effect remains uniform, avoiding the patchy look that cheaper panels often develop with time.

Raymates Quality Assurance System

Every single sheet gets tested completely before it leaves the factory. They follow ISO9001 rules and the strict 6S system. All products have UL, CE, RoHS, and ETL certifications. That means almost zero color differences, dead LEDs, or early failures. Customers get reliable panels that just keep working.

What Preventive Actions Can Further Lower Maintenance Costs?

Preventive steps are easy to follow and save money over time. These habits do not require big budgets or special skills, but they keep LED sheets running well for much longer.

Professional Installation Support

Some projects, especially those with curved shapes or layered designs, benefit from professional help. Raymates provides support, drawings, and installation guidance for complicated layouts. This makes the final setup cleaner and reduces mistakes that might lead to problems later. Good planning at the start prevents many future issues.

Environmental Protection Measures

The surrounding environment affects LED performance. In humid places, waterproof or sealed designs help stop moisture damage. Outdoor signs or areas with long sun exposure need materials that resist UV and heat. Even indoor spaces can benefit from minor protection steps if the climate varies through seasons. A few small adjustments keep maintenance needs low.

Long-Term Maintenance Scheduling

A simple schedule works better than waiting for problems to appear. Checking for brightness drop, cleaning dust, testing connectors, and replacing small accessories early keeps the system healthy. Businesses that already track other maintenance items can easily add LED panels to the routine.

FAQs

Q1: How often should LED panels be cleaned?

A: In normal indoor places, every 1–3 months is enough. Busy shops or restaurants might do it monthly.

Q2: What shortens LED sheet lifespan the most?

A: Too much heat, moisture, wrong voltage, and rough handling are the main culprits.

Q3: Are Raymates LED sheets suitable for curved surfaces?

A: Yes — both the Lensed LED Sheet and Matrix LED Sheet bend easily and can be cut to fit almost any shape perfectly.