LED light sheets have reshaped the way designers think about backlighting. Their ultra-thin structure, smooth glow, and ability to fit into tight spaces make them a practical choice for today’s hospitality, retail, and residential projects. As lighting moves toward cleaner lines and hidden sources, LED sheets step in as a stable and adaptable base layer. Raymates—a manufacturer with long-term certifications and global export experience—continues to expand this category with its Lensed LED Sheet and Matrix LED Sheet solutions.

Why Are LED Light Sheets Becoming Essential in Modern Lighting Design

The growing demand for clean visual surfaces and uniform illumination explains why LED sheets appear so frequently in new-build and renovation projects. A quick look at industry numbers shows how fast related technologies (COB, LED panels, flexible lighting systems) are expanding.

Ultra-Thin Structure and Smooth Light Output

Thin light sources are driving many of the trends in modern architectural and retail lighting. Recent market research reflects this shift toward compact, uniform systems.

Table 1. Global Market Growth of Core Technologies Behind LED Light Sheets

| Technology Category | 2023 Market Size | Forecast 2030 | CAGR | Key Driver |

|---|---|---|---|---|

| COB LED Market | USD 2.2B | USD 8.4B | 15.8% | Demand for high-density, uniform light |

| LED Neon & Flex Lighting | USD 1.26B | USD 2.4B | 6.5% | Need for flexible architectural lighting |

| LED Backlighting Systems | USD 10.1B | USD 16.2B | 7.0% | Use in retail, hospitality, display systems |

These trends explain why designers choose slim, even light sheets over older strip-based setups that can create bright spots. The Lensed LED Sheet, in particular, uses micro-lens structures for wider beam distribution, blending light faster even in shallow cavities.

Flexible Use Across Residential and Commercial Projects

From curved shelves to irregular bar counters, LED sheets adapt to surfaces that once required complicated fixtures. Raymates has supported multiple such installations, including a marble bar counter project where a flexible LED sheet was cut and folded around tight corners to create warm backlighting.

Stable Performance in Long-Term Applications

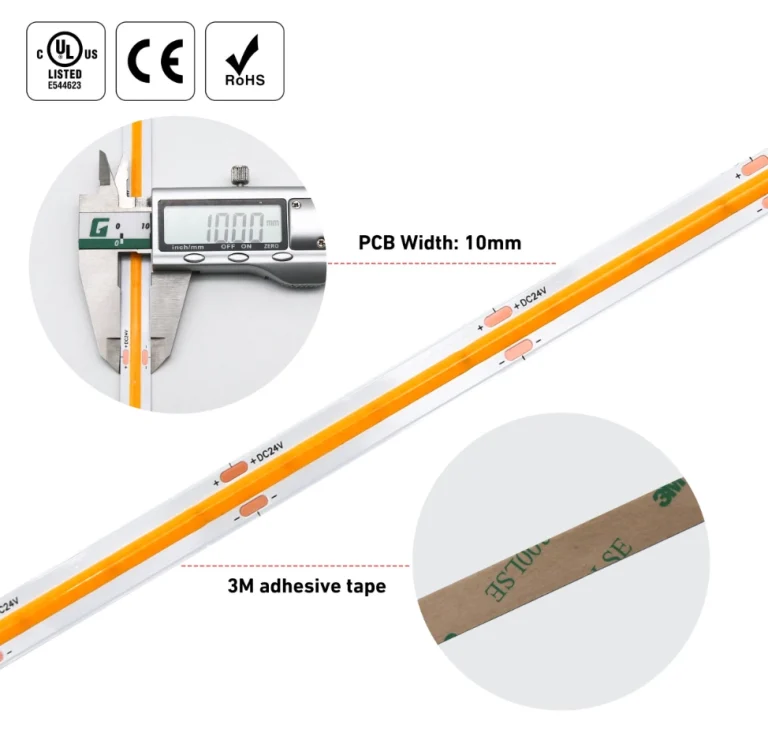

High color accuracy (CRI ≥ 90) and long lifespans around 50,000 hours make LED sheets dependable in retail, hospitality, and display environments. Raymates’ manufacturing approach—built on ISO9001 and 6S management—supports this reliability, complemented by UL, ETL, CE, RoHS, and TUV certifications.

How Do LED Light Sheets Work Behind the Surface

A closer look at their structure helps explain why LED sheets create such a smooth effect compared to individual strips or point sources.

Light Distribution Through Lens or Matrix Layout

Raymates’ Lensed LED Sheet spreads light through tiny lenses placed above each diode, increasing the beam angle and reducing hotspots. The Matrix LED Sheet, with LEDs arranged in a uniform grid, produces consistent brightness across larger surfaces such as signage or retail showcases.

To highlight how uniformity compares across technologies, here’s a simple data snapshot used by lighting planners:

Table 2. Typical Light Uniformity Comparison

| Lighting Method | Typical Min/Max Uniformity Ratio | Risk of Hotspots | Ideal Use Case |

|---|---|---|---|

| Standard LED Strips | 1:3 – 1:6 | High | Under-cabinet, linear slots |

| COB Strips | 1:1.5 – 1:2 | Medium | Decorative lines, narrow backlighting |

| LED Light Sheets (Lensed/Matrix) | 1:1.1 – 1:1.3 | Very Low | Stone backlighting, displays, signage |

Uniformity is the main reason LED sheets are preferred for luxury stone features, cosmetic counters, and shallow architectural pockets.

Electrical Design and Cuttable Segments

LED sheets work on constant-voltage drivers (5V–48V or high-voltage 110–230V depending on the project). Many cheaper products fail because cut marks are unclear or the copper traces are too thin—leading to short circuits when trimmed. Raymates uses thicker copper pathways and precise cutting intervals to reduce these risks.

Heat Management and Material Durability

Even thin panels need proper heat control. Strong thermal substrates, SMT assembly, reflow soldering, and full aging tests contribute to Raymates’ durability. Their production line includes SONY SMT machines, laser printers, and integrating spheres for optical measurement, supporting consistent quality across batches.

What Makes Raymates LED Light Sheets Different From Other Suppliers

While many brands sell sheet-style lights, their internal engineering, stability, and consistency can differ sharply.

Lensed LED Sheet for High-Precision Backlighting

This sheet is built for translucent materials—stone, acrylic, frosted glass—where minor shadows become highly visible. Its optical lens structure spreads light effectively in shallow spaces where conventional backlighting struggles.

Matrix LED Sheet for Creative and Custom Layouts

Matrix sheets support one-light-one-cut layouts, making them easy to flex or fold around corners. In a bar counter installation, Raymates’ flexible LED sheet modules wrapped around intricate edges while maintaining consistent color and brightness.

Proven Manufacturing Quality and Global Certifications

Raymates exports to more than 30 countries and performs 100% QC checks before shipment. This matters because batch inconsistencies—brightness or CCT shifts—are a major industry pain point.

Here is a snapshot of how different regions are driving demand for high-quality backlighting products:

Table 3. Regional Demand for LED Backlighting & Sheet-Based Lighting

| Region | Market Share | Growth Driver | Typical Projects |

|---|---|---|---|

| Asia-Pacific | 30%+ | Smart cities, retail expansion | Architectural backlighting, signage |

| North America | 25% | Hospitality renovation cycles | Hotels, casinos, bars |

| Europe | 22% | Energy regulations | Museums, branded retail |

| Middle East | 10% | New commercial development | Malls, luxury interiors |

These regions align closely with where Raymates already ships its LED products, supported by certifications required for international projects.

Where Can LED Light Sheets Be Used in Real Projects

The versatility of LED sheets provides solutions for surfaces that benefit from diffused illumination.

Backlit Stone and Architectural Surfaces

Hotels, lounges, and luxury homes frequently choose light sheets to illuminate onyx, marble, or semi-translucent composite stone. The even glow highlights the natural pattern without revealing diode points.

Retail Display and Product Showcases

Cosmetics counters, jewelry displays, and branded lightboxes need stable brightness and color accuracy. Industry data shows high-CRI backlighting increases product dwell-time and visual impact, especially in beauty retail. Dark edging—common with cheaper sheets—is greatly reduced when LED spacing and optical diffusion are engineered correctly.

Creative Interior and Bar Counters

Restaurants and entertainment spaces often use LED sheets behind textured surfaces. In Raymates’ bar counter project, the flexible sheet created a warm, inviting glow under marble panels, helping establish the visual theme of the space.

How To Select the Right LED Light Sheet for Your Project

Choosing the right sheet can significantly affect brightness, uniformity, and installation time.

Optical Requirements and Lighting Effects

Lensed sheets are a strong choice for shallow applications, while matrix sheets offer predictable output for large-format installs. Material transparency also guides the selection.

Installation Environment and Voltage Options

Raymates provides low-voltage (3V–48V) and high-voltage (110–230V) ranges to match global systems. This flexibility helps reduce driver count in large installations such as hotel corridors or signage systems.

Custom Sizes, Cutting Lines, and Driver Matching

Drivers must match the sheet’s voltage and current profile. Many buyers report mismatched drivers as a top cause of early failure. Raymates’ engineering team frequently supports customers with layout drawings and driver recommendations.

What Are the Latest Trends in LED Light Sheet Technology

The category is still evolving, and several trends are shaping its future.

Thinner Modules and Higher Efficiency Designs

Manufacturers now create 1–3 mm panels with higher lumen-per-watt output, responding to both design and energy targets worldwide.

Smart Dimming and Zonal Control Options

PWM dimming, 0–10V interfaces, and smart controls appear more often in sheet-based lighting. Some sectors—education, exhibitions—are asking for zonal control, though this feature is still limited in many sheet systems.

Growth in Hospitality, Retail, and Architectural Projects

Global construction and renovation cycles are pushing the LED sheet market upward. Backlit stone, signage, and large-format displays continue to adopt sheet formats for their clean, consistent appearance.

FAQs

Q1: Are LED light sheets better than traditional LED strips for backlighting?

A: LED strips perform well for linear applications, but sheets provide smoother, more even illumination for surfaces like stone, acrylic, or lightboxes. Their structure helps eliminate visible hotspots.

Q2: Can LED light sheets be cut into custom shapes?

A: Yes. Most sheets include marked cutting lines. Raymates offers modules with one-light-one-cut designs for irregular layouts.

Q3: What materials work best with LED light sheets?

A: Translucent stone, acrylic, onyx, signage panels, and decorative textures all respond well to sheet-based backlighting because the light spreads evenly across the surface.