COB LED strips give off awesome, even light, but their tight chip setup makes a lot of heat that can mess with performance and how long they last. Good cooling, from the materials used to how they’re set up, keeps them running strong without dimming or color changes. This guide looks at how RAYMATES’ tough COB strips handle heat while shining bright, perfect for stores, buildings, and factories.

The Structure and Heat Generation Mechanism of COB LEDs

COB LED strips are made by sticking tons of LED chips right onto a board, creating a bright, smooth light source. This setup skips individual chip covers, boosting light output and hiding tiny light dots. But packing chips so close means heat builds up in a small space.

Each chip turns power into light, but not all of it. A big chunk—about 60% to 80%—turns into heat. In COB strips, with lots of chips jammed together, this heat can pile up fast if you don’t handle it right.

When power flows through each chip’s core, it creates heat from resistance. With dozens or hundreds of chips on one strip, the heat adds up quick. You need solid cooling to keep things under control.

Factors Influencing Temperature Rise in COB Strips

A COB strip’s heat depends on a few things working together:

- Power Input: More watts per meter means more heat.

- Room Temp: Hot surroundings make cooling trickier.

- Board Material: FR4 boards hold heat; aluminum ones spread it better.

- Setup Style: Tight spaces trap heat; open setups let air flow.

- Mounting Surface: Non-metal or bad conductors block heat transfer.

These factors decide how hot your COB strip gets. Without good control, too much heat can break it or make it less bright.

Importance of Thermal Management in COB LED Applications

Why care about heat? It directly hits how well COB strips work and how long they last.

Too-hot chips can dim over time, shift colors, or even wreck the coating or sealing stuff. Plus, high temps can wear out circuits and connections faster.

Good cooling keeps light steady and helps the strip hit its full lifespan. It also lets you push the strip harder without risking safety or performance.

Industry Standards and Guidelines for COB Strip Temperatures

Industry rules set safe heat levels based on chip temp (Tj). For most COB strip LEDs, makers say keep Tj under 85°C for normal use. Never go above 125°C, or you’re asking for trouble.

Tests like IEC 62717 or LM-80 check how long strips last in controlled heat settings. These help you know if your setup stays safe for different uses.

Recommended Operating and Maximum Junction Temperatures

For best results and long life, keep chip temps between 60°C and 85°C during steady use. Chips can handle 120°C–150°C before breaking, but staying way below that stretches their life big time.

In tight fixtures or hot places like factories, you might need to lower power or beef up cooling to stay safe.

Thermal Derating Curves and Their Application in System Design

Thermal derating curves show how light output or power changes with heat. They’re super handy for planning setups because they tell you when performance drops as temps climb.

By checking these charts from makers, you can pick safe power levels for certain temps. This keeps your COB strip running smooth without hitting heat limits.

In fancy setups like cove lighting or store displays, where looks and toughness both matter, these curves are a must.

Overview of RAYMATES’ Thermal Design Philosophy

RAYMATES builds COB strips with care. They focus on cooling through smart material picks, clever circuit designs, and pairing with standard aluminum frames.

What makes them stand out is their focus on lasting strong, even in tough spots like small spaces or long runtimes at full blast. If you want a lighting partner that mixes new ideas with practical fixes, RAYMATES is a solid pick—not just for products but for help from prototype to big projects.

Typical Operating Temperature Ranges for RAYMATES COB Strips

RAYMATES COB strips usually run at surface temps of 45°C–65°C when stuck on aluminum frames in rooms cooler than 30°C. Their cooling setup keeps chip temps safe, even at max brightness for hours, thanks to low power use and smart chip spacing along the strip.

This makes them great for places like hotels or shops that need lights on for over 12 hours a day.

Comparative Analysis: RAYMATES vs. Market Alternatives

Compared to cheap alternatives with thin boards or weak coatings, RAYMATES COB strips stay cooler under the same load. That means better light output and fewer breakdowns over time.

They use top-notch copper paths and heat-friendly glue to boost reliability. This matters a ton in critical spots like hospitals or museums, where light consistency can’t slip.

Effective Heat Dissipation Techniques for COB Strips

To keep heat in check:

- Use aluminum channels with lots of surface area.

- Stick on heat-conducting tape between the board and mount.

- Don’t coil extra strip length in tight spaces.

- Leave gaps for air around fixtures when you can.

These simple tricks usually work for indoor setups unless room temps hit 40°C a lot.

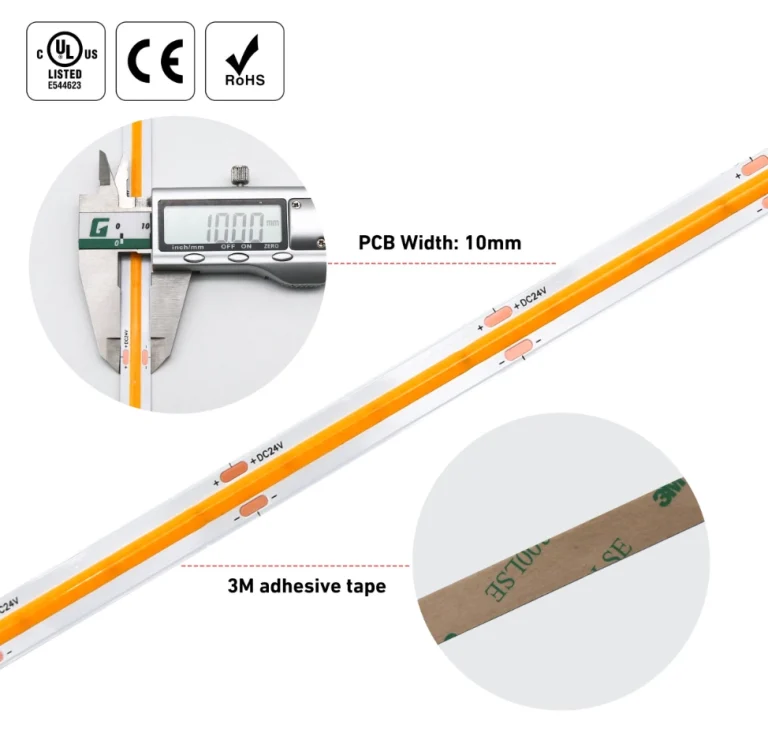

Role of Substrate Materials and PCB Design in Thermal Control

Picking between FR4 fiberglass boards and aluminum-core ones makes a big difference. Aluminum boards spread heat way better (about 200 W/m·K vs. 0.3 W/m·K for FR4).

Wider copper paths cut down on heat from resistance. Multi-layer designs spread power evenly, too. Both help keep temps low across the strip.

Use of Aluminum Profiles and Passive Cooling Solutions

Aluminum frames do two jobs—they hold the strip and act as a heat sink. When paired with heat-conducting tape, they pull heat right off the board’s bottom to the metal.

For super-narrow channels with little air, slim aluminum frames are key for both support and cooling.

Indoor vs. Outdoor Installation Conditions

Where you put COB strips changes how they handle heat:

- Indoor: Steady room temps (20–25°C) make cooling easier.

- Outdoor: Sunlight or changing weather can push enclosure temps over 50°C before the strip even turns on.

For outdoor use, lower power or add active cooling. Or pick strips with UV-proof coatings and waterproof seals.

Impact of Ambient Temperature on COB Strip Lifespan

Every 10°C jump in chip temp can cut an LED’s life in half, based on aging models. To hit the rated 50,000 hours—or more—keep the area cool with good vents and smart material choices.

Even small steps, like avoiding spots near HVAC vents or tight ceilings, make a difference over time.

Application Scenarios: Architectural, Retail, Industrial Lighting

Different uses have different needs:

- Architectural Lighting: Looks matter most. Low-profile strips with hidden heat sinks shine here.

- Retail Lighting: Needs steady brightness. Stable heat keeps colors true all day.

- Industrial Lighting: Toughness is key. Wide temp ranges handle warehouse or factory conditions.

Matching strips to your setting ensures great looks and performance.

Product Recommendations from RAYMATES Based on Thermal Requirements

For hot spots like kitchens or factories, RAYMATES’ High-Efficiency Series saves power and keeps chips cooler under heavy use.

For bendy setups like signs or furniture, their Flexible COB Strips have tough boards that resist cracking from flexing while staying cool.

For slim spots like display cases or stair steps, where air’s tight but brightness can’t dip, their Ultra-Narrow COB Strips deliver solid light without overheating, thanks to smart, compact designs.

Upgrade to COB strips built for performance—explore RAYMATES’ thermally optimized solutions today!

FAQ

Q: What’s the normal surface temp range for a good COB strip?

When mounted on aluminum in rooms under 30°C, quality COB strips run at 45°C–65°C during regular use.

Q: Can I put COB strips in sealed fixtures?

Sure, but lower power or use strips made for tight spaces with less air, or heat will build up.

Q: How does board material affect LED life?

Aluminum-core boards spread heat better than FR4. This lowers chip temps, slowing wear and boosting lifespan.