Lighting has come a long way from bulky tubes and rigid panels. In today’s world of interior design and commercial display, everyone is looking for something that is slim, flexible, and easy to install. That’s exactly where LED sheet lighting makes its mark. Whether you’ve seen a glowing onyx countertop in a five-star hotel bar, or a perfectly lit cosmetic shelf in a shopping mall, chances are you were looking at LED sheets doing the heavy lifting.

At RAYMATES, a global supplier with more than a decade in the LED industry, we see LED sheets not just as another product but as a practical tool for designers, retailers, and builders. In this blog, we’ll explore why LED sheets are so thin and flexible, how they achieve uniform light, and where RAYMATES’ Lensed LED Sheet and Matrix LED Sheet fit into real-world projects.

What Materials Allow LED Sheets to Be Ultra Thin

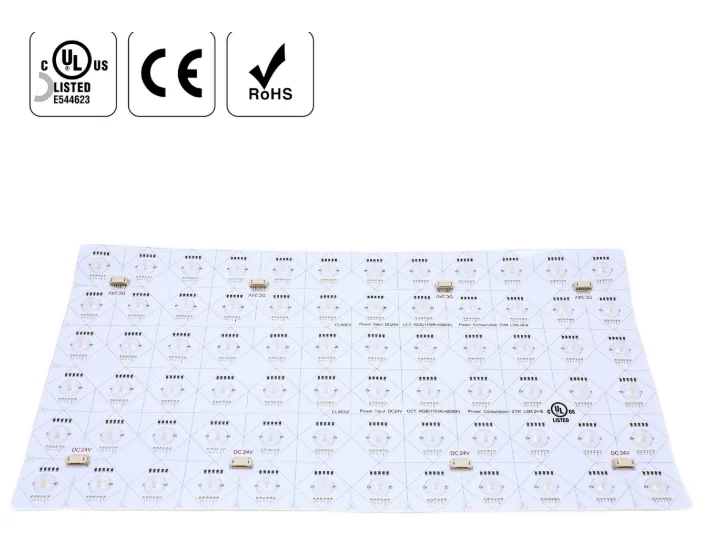

Lightweight PCB Substrate

The secret behind a thin LED sheet lies in its backbone: the printed circuit board. Instead of heavy aluminum plates or glass, LED sheets typically use lightweight PCBs that can be made as thin as 1–2 mm. This reduces both the overall thickness and the weight, making installation a lot easier than with traditional light boxes. For contractors, this means less stress on walls or ceilings—no need for reinforced brackets or complicated mounts.

Flexible Copper Circuit Design

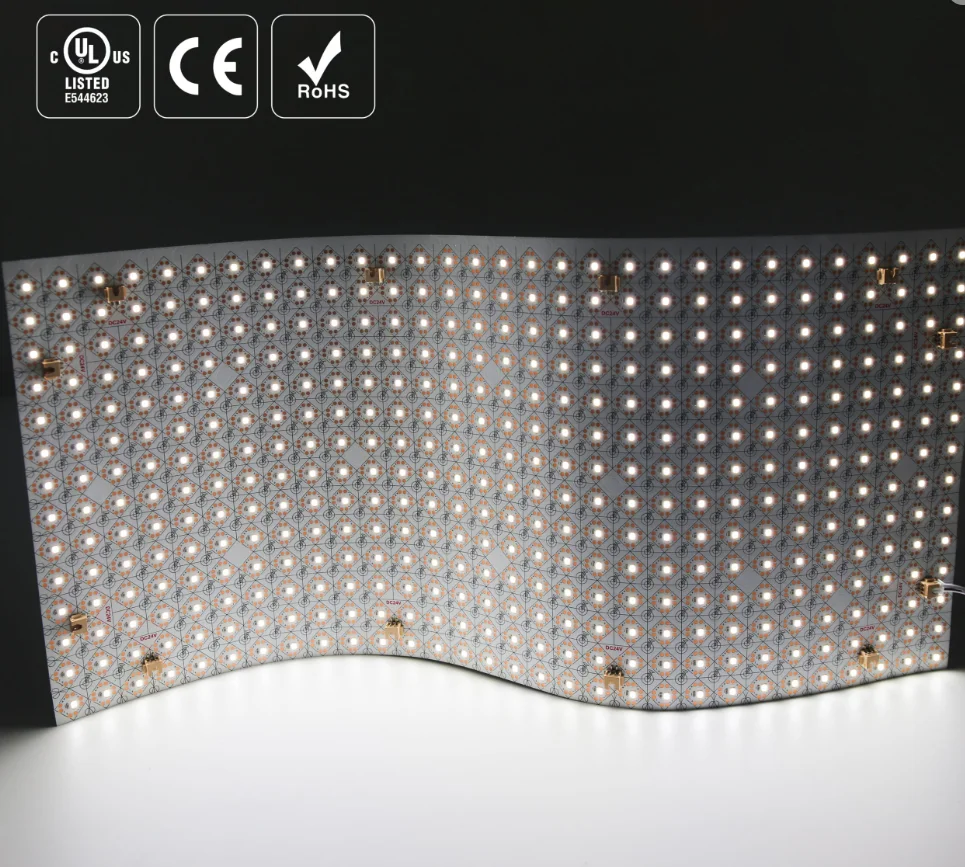

A flexible copper circuit gives the sheet its “bendability.” This allows installers to curve the panel around rounded columns, arc-shaped ceilings, or even custom furniture pieces. In retail spaces, where every corner counts, the ability to wrap light neatly around edges without breaking continuity makes a big difference. You can think of it as rolling wallpaper, only this wallpaper glows.

Slim Optical Diffuser Layer

Finally, a diffuser film is added to spread the light evenly. Unlike bulky acrylic panels, today’s diffusers are paper-thin yet effective. They eliminate the harsh LED dots and turn the sheet into a smooth glow source. It’s almost surprising when you touch it—the panel feels no thicker than a few sheets of cardboard, yet it lights up an entire display.

How Does Flexibility Change LED Sheet Applications

Curved Surface Backlighting

Designers love to use LED sheets behind curved stone walls or wavy ceiling features. Traditional rigid panels would crack or leave gaps, but flexible sheets bend without breaking. One of our clients in Europe used Matrix LED Sheets to backlight a spiral staircase wall, creating a futuristic look that’s still talked about by visitors.

Edge and Corner Installations

Flexibility also shines when it comes to tricky edges. In hotel lobbies, for example, LED sheets can fold around reception counters with sharp corners, avoiding dark spots. The “one light one cut” design from RAYMATES makes it easy to trim panels exactly to size, minimizing waste and fitting neatly into tight spaces.

Artistic and Custom Shaped Projects

Architects are no longer limited to squares and rectangles. With LED sheets, cutting custom shapes—like a brand logo or a pattern—is not only possible but cost-effective. A retail chain in the Middle East used customized sheets to illuminate their wall-sized logo, turning it into both signage and decoration.

Why Is Light Distribution So Uniform in LED Sheets

Precise LED Spacing and Lensing

Uniform light is not magic; it’s engineering. LEDs are placed with precise spacing, often around 20 mm apart, to avoid gaps or overlaps. In the case of RAYMATES’ Lensed LED Sheet, each diode comes with a tiny optical lens that spreads light more evenly, reducing hot spots.

High CRI and Consistent Brightness

Color rendering is critical in settings like clothing stores or cosmetic counters. A CRI (Color Rendering Index) above 90 means that the colors of fabrics or makeup look natural and attractive. Nobody wants a dress to look sky blue under the store lights and dull gray at home.

Reduced Dark Spots at the Edges

Cheap panels often suffer from dim edges, especially when cut. RAYMATES designs its sheets with overlapping light zones, so even the trimmed parts maintain brightness. For marble countertop projects, this avoids the dreaded “glowing center, dark border” problem.

What Makes RAYMATES Lensed LED Sheet Stand Out

Enhanced Beam Control with Optical Lens

The built-in optical lenses give this sheet a unique edge. They help spread the light across wide surfaces, making it ideal for backlighting translucent stone like onyx or quartz. It’s almost like turning stone into a glowing artwork.

Energy Saving and Long Lifespan Performance

With a rated lifespan of over 50,000 hours, these sheets are not only bright but also reliable. Running costs are lower, and replacements are rare. Many of our hotel clients find that once installed, the sheets perform for years with minimal maintenance.

Ideal for Cosmetic Counters and Onyx Stone Backlighting

In high-end retail, presentation is everything. The Lensed LED Sheet has been widely used in cosmetic counters, giving products a vibrant, premium look. For architects, placing it under translucent stone creates that “wow factor” without needing bulky hardware.

How Does the RAYMATES Matrix LED Sheet Improve Design Freedom

Modular Grid Layout for Easy Cutting

The Matrix design uses a grid system, making it incredibly easy to cut into smaller modules. For projects like lightboxes, signage, or irregular ceiling layouts, installers can shape the sheet without damaging the circuit.

Seamless Connection for Large Surfaces

Multiple sheets can be tiled together seamlessly. A shopping mall project in Germany used over 50 panels of Matrix LED Sheets to light an entire glass atrium, and visitors couldn’t spot where one panel ended and the next began.

Stable Brightness for Commercial Displays

Unlike some products that dim when extended, Matrix LED sheets maintain stable brightness even across large areas. This consistency is crucial in commercial spaces where every product on display deserves equal light.

What Installation Advantages Do LED Sheets Offer

Plug and Play Driver Compatibility

Most LED sheets from RAYMATES work with simple plug-and-play drivers. Electricians don’t need to spend hours on wiring. Even small business owners sometimes handle the setup themselves, saving on labor costs.

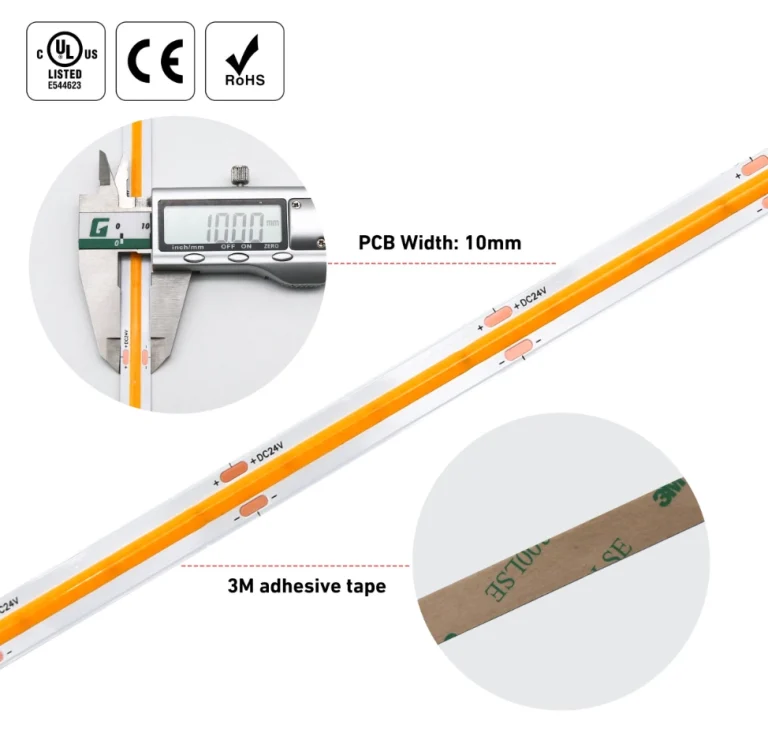

Simple Adhesive or Screw Mounting

Mounting options are flexible—literally. For smooth walls, 3M adhesive works fine. For curved or heavy surfaces, installers can use screws or aluminum channels. It’s not rocket science; it’s straightforward.

Lightweight Panels for Quick Setup

Because each panel is light, shipping costs are lower, and handling is easier. For international clients, that’s a real money-saver. No one likes to pay extra just because packaging is oversized.

Why Are LED Sheets a Smart Choice for Future Lighting Projects

Sustainable and ROHS Compliant Materials

No mercury, no UV radiation, and full ROHS compliance make LED sheets an eco-friendly choice. In an era where clients increasingly ask about “green” building materials, having compliant lighting products matters.

Versatility Across Residential and Commercial Spaces

From kitchen islands to large-scale hotel lobbies, LED sheets adapt to many environments. A single technology serving multiple markets is always a smart investment.

Proven Reliability from RAYMATES Global Projects

With exports to over 30 countries—including the U.S., Germany, and Saudi Arabia—RAYMATES’ LED sheets have been tested in diverse climates and project types. This global footprint is part of why international partners keep coming back.

FAQs

Q1 What is the difference between Lensed LED Sheet and Matrix LED Sheet

The Lensed LED Sheet focuses on beam control and uniform diffusion, great for backlighting translucent surfaces like stone or glass. The Matrix LED Sheet, on the other hand, uses a modular grid for easy cutting and large-area coverage, making it better for signage and commercial displays.

Q2 Can LED sheets be cut on-site without damaging them

Yes, RAYMATES designs both Lensed and Matrix LED Sheets with marked cutting lines. As long as you cut along the designated spots, the sheet continues to function normally.

Q3 How long do LED sheets typically last in real projects

With high-quality LEDs and proper installation, RAYMATES sheets are rated for 50,000 hours or more. In practice, that means several years of continuous use before brightness drops noticeably.