Introduction

LED light panels are now a key lighting option in business, building, and decor jobs. Their thin shape, small power draw, and clear, steady shine suit spots like hotels, shops, and show counters well. Yet, even top LED setups can run into trouble if upkeep gets skipped. Too much heat, blinking lights, or quick fade show up way before the hoped-for end—often from wrong handling or bad stuff inside.

Raymates, a solid LED lighting maker with over 15 years in the field, has earned a good name for making trusty, strong LED sheets. Among their top items, the Lensed LED Sheet and Matrix LED Sheet mix smart build and tough parts to give steady work with little care.

Why Does LED Light Panel Maintenance Matter?

Extending Product Lifespan

Steady care lets LED panels stay near their first brightness for a long time. Grime, dust, and extra warmth slowly hurt how they work. This cuts their life short. But with easy wipes and good air flow, the boost in toughness can be big. Some panels can run thousands of hours more.

Preventing Downtime in Commercial Applications

In a shop or hotel front, light breaks are more than a bother. They harm the feel and brand look. So, keep panels dust-free. Check wires often. Care for drivers too. These steps dodge those odd dark areas that spoil a nice spot.

Reducing Long-Term Replacement Costs

Swapping out many panels costs a lot. Tiny care tasks, like looking at plugs or fixing bad drivers soon, can slash large fix bills down the road. This kind of work holds lighting steady. It saves both hours and cash.

Good upkeep does not just guard gear. It guards what you spent. And for lasting trust, the right item build counts as much as care ways.

What Common Issues Lead to Premature LED Panel Failure?

Overheating and Poor Heat Dissipation

LED chips hate high heat. If warmth has no way out, parts fail. Brightness falls quick. Slim metal backs or bad air make it worse—mainly in closed shows or tops.

Moisture Ingress and Electrical Damage

Wet air can rust joins or spark short outs. In places like baths, bars, or beach spots, water-proof seals or better IP marks are key. Even tiny damp inside a panel can start blinks and part light drops.

Voltage Instability and Driver Mismatch

Picking the wrong driver or shaky power burns paths and makes uneven shine. Lots of cheap panels quit early since they match wrong power levels, like 12V drivers on 24V panels.

Knowing these soft spots aids folks pick panels made to deal with them—like those from Raymates. They aim for steadiness and toughness in daily runs.

How Do Raymates LED Sheets Enhance Durability and Stability?

High CRI and Uniform Illumination Design

The Lensed LED Sheet has exact light lenses that spread glow even. They cut dark sides or hot spots. It gives a smooth, even shine great for back lights on stone, glass, or plastic shows where steady light means a lot.

Advanced PCB and Thermal Management

The Matrix LED Sheet uses a board that moves heat fast. It keeps LEDs cool and steady. This setup cuts light fade and aids each panel hold its color match even after years of use.

Certified Quality and Global Standards

Raymates products pass world checks like UL, CE, and RoHS. These nods show true-world trust, whether in wet hotel bars or long-run show boxes.

By mixing strong stuff with smart plans, Raymates eases the care load on users. They offer lighting that really holds up.

What Maintenance Practices Keep LED Panels Performing Like New?

Regular Cleaning and Dust Control

Even a light dust coat can block shine and hold heat. Use a soft, dry rag or gentle air puff to wipe panels once a month. This holds brightness and stops too much warmth. Skip cleaners with booze that could harm coats.

Proper Ventilation and Temperature Monitoring

Nice air around panels lets heat slip away easy. In business spots, add simple air holes or use metal paths. These can stop heat jumps that age LEDs too soon.

Checking Power Supply and Connectors

Loose joins or worn drivers cause blinks and push paths hard. Do a fast check every few months—mainly before busy times or heavy use. This keeps all smooth.

Small moves, done often, build to years of steady light and good runs.

How to Handle Installation and Environmental Factors for Maximum Longevity?

Using Correct Adhesives and Mounting Methods

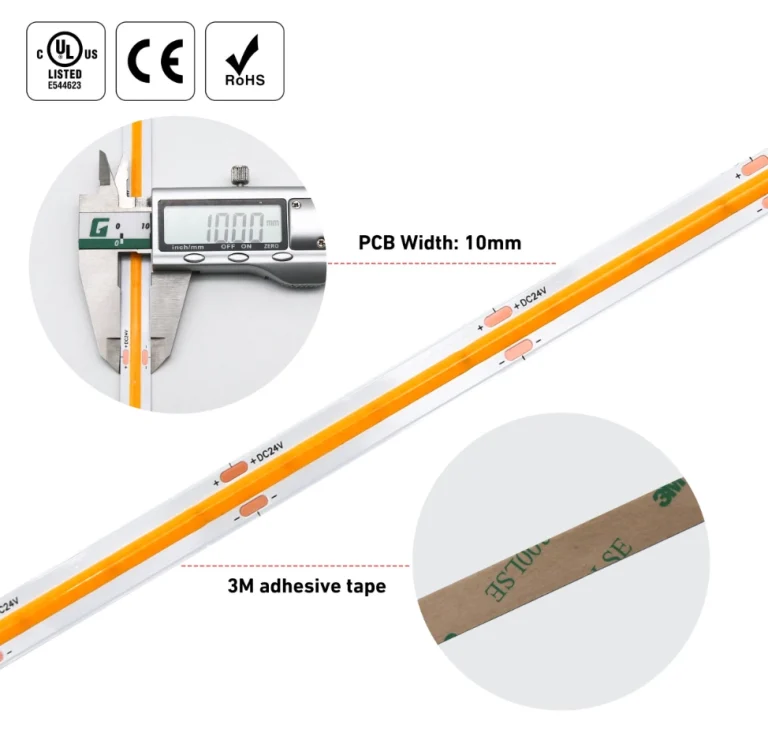

Bendable LED sheets need firm, heat-proof glues. Normal tapes lose hold over time, mainly on curved spots. Good picks like 3M 9448A aid panels stay fixed and keep steady touch with surfaces.

Avoiding Extreme Humidity and Direct Sunlight

Steady wet or straight sun can turn spread layers yellow and weaken paths. Set panels far from direct hits. This holds the light pure and steady in shade.

Storing and Transporting Panels Properly

Before setup, LED sheets should sit flat and dry. Bending or squashing bendy boards can make hidden breaks that lead to fails later. Raymates uses static-proof packs and bubble wrap to guard each load in move.

Sticking to these hold ways is one of the easy paths to skip needless panel swaps down the line.

When Should You Replace or Upgrade LED Panels?

Detecting Signs of Lumen Decay or Flicker

Getting dim or odd blinks often means inside parts wear out. Check shine after many thousand hours. This aids track how they do over time.

Evaluating Energy Efficiency Over Time

Old LED panels might still run but use more juice for the same shine. New builds—like the Raymates Lensed LED Sheet—give better light with less power.

Considering Raymates Lensed and Matrix LED Sheets for Upgrades

For jobs set to boost, these two types are solid picks. The Lensed LED Sheet fits building back lights well. The Matrix LED Sheet works for big business surfaces that need steady shine. Both are simple to set and work with most power setups.

A boost at the right spot brings back light grade and cuts run costs for years on.

What Are the Benefits of Choosing Raymates for Long-Term Projects?

15+ Years Manufacturing Expertise

Since 2009, Raymates has aimed at LED lighting new ideas. They mix SONY SMT machines and 6S ways to handle each make step. This base ensures steady grade in every panel.

OEM/ODM Customization for Project Needs

From power picks (3V–230V) to size tweaks, Raymates backs custom fixes for builders, planners, and sellers around the world. Tailor lights can fit plan thoughts without losing toughness.

Comprehensive After-Sales and Installation Support

Raymates gives clear setup guides, video helps, and quick client aid. Folks in over 30 lands trust their tech group for fast aid and pro fixes.

Mixing deep skills with trusty help, Raymates aids buyers hit lasting light wins that seldom need fixes or swaps.

Conclusion

Nice lighting holds longer when cared for. Daily upkeep, right spots, and solid items team up. Raymates’ Lensed LED Sheet and Matrix LED Sheet are made with that thought—they offer shine that stays even, stuff that fights wear, and work that cuts breaks.

For light planners, workers, and shop owners who want to skip early breaks, picking tough panels and holding easy care ways can change things. With Raymates, long life is not just words—it’s in each sheet.

FAQs

Q1: How often should LED light panels be cleaned?

A: Once every 4–6 weeks works for business spots. In dusty or busy areas, wipe more often to stop buildup that hurts light out.

Q2: Can LED panels be repaired if part of them stops lighting up?

A: At times. If just a few LEDs quit, the trouble might be with plugs or drivers. But for wide dim or blinks, a swap is often quicker and cheaper.

Q3: What makes Raymates LED Sheets different from generic panels?

A: Raymates uses top board stuff, exact LED gaps, and checked parts under ISO9001 rules. The outcome is panels with steady color, low heat out, and a life over 50,000 hours—great for hard business light jobs.