Lighting has never been only about brightening up a space. It also sets the tone, highlights the right details, and even makes materials come alive. In the last few years, one product has been getting more attention in the lighting world—LED sheets. Unlike big, heavy fixtures or stiff panels, LED sheets are light, slim, and very flexible. Companies like Raymates are taking this idea forward with well-made, cuttable, and certified solutions that meet the needs of both designers and businesses.

This article explains why LED sheets are becoming so popular and why Raymates stands out in this growing trend.

What Makes LED Sheets Different from Traditional Lighting

Flexible and Ultra Thin Design

If you walk into a stylish hotel lobby or a high-end store, you may see light glowing evenly under a marble counter or behind curved walls. In many cases, that glow comes from an LED sheet. These sheets are only a few millimeters thick. They can fit in places where old lights simply cannot. Some even bend slightly, making them perfect for rounded or uneven surfaces. Designers no longer need to give up their bold ideas because of bulky lighting equipment.

High CRI and Uniform Illumination

When it comes to lighting, color accuracy really matters. Think about a store selling lipsticks—if the shade looks dull under bad lighting, customers won’t buy it. Raymates LED sheets reach CRI 90 or higher, which means colors look true and vivid. Another important part is the even layout of LEDs on the sheet. This gives smooth light without dark spots or uneven patches, a problem often seen in low-cost products.

Energy Saving and Long Lifespan

Changing lights every year is not fun, especially in large spaces. LED sheets can last 50,000 hours or more, which equals about five years of nonstop use. They also use far less electricity compared to old-style fluorescent panels. For hotels with hundreds of rooms or shops with many display areas, this saves a lot of money in the long run.

Why Are LED Sheets Popular in Commercial and Residential Projects

Versatile Applications in Interiors and Retail

LED sheets are like the “all-in-one” tool of lighting. In homes, people use them under kitchen countertops or behind TV walls. In shops, they are placed in display cabinets to make products stand out. Raymates has supplied LED sheets for projects in Europe and the Middle East. Customers liked the sleek look and the fact that these solutions did not need heavy construction.

Seamless Integration with Backlit Materials

Materials like stone, glass, and acrylic look beautiful when lit from behind. But the lighting must be smooth to look good. LED sheets make this possible. A good example is when Raymates MATRIX LED SHEET was used under an onyx stone bar counter. The glowing surface instantly became the center of attention. What the client received was not just lighting but an inviting atmosphere.

Customized Sizes and Easy Installation

Every project has its own size and style needs. Some require small panels, while others need entire walls lit up. Raymates offers LED sheets that can be cut to marked points and linked together. This avoids wasted material and saves time during installation. In many cases, the system is simple plug-and-play, which also lowers labor costs.

How Do LED Sheets Solve Common Lighting Challenges

Elimination of Dark Spots and Uneven Edges

One of the biggest issues with older backlighting methods is the shadow at the edges. LED sheets fix this by keeping LEDs at steady distances from each other. This way, the whole panel lights up evenly. This is especially important in large advertising lightboxes, where uneven light can ruin the effect.

Reliable Cutting and Power Matching

Cutting LED sheets wrongly can cause short circuits, especially in poor-quality products. Raymates solves this problem with clear cutting marks and well-matched drivers. Whether a project uses 12V or 24V power, their team can guide customers to the right choice.

Secure Fixation on Curved Surfaces

Mounting flexible panels on curved walls is not as simple as it looks. Normal double-sided tape may work for a while but often comes off. Raymates suggests industrial adhesives or screw-fixed methods. This way, the sheet stays firmly in place, even after long-term use.

What Are the Advantages of Raymates LED Sheet Products

MATRIX LED SHEET for Modular Flexibility

The MATRIX LED SHEET is designed for projects that need flexibility in scale. Each sheet can be cut and joined, making it work like building blocks. This makes it ideal for big projects like retail walls or creative signage.

LENSED LED SHEET for Superior Light Diffusion

The LENSED LED SHEET has tiny lenses over each diode. These lenses spread the light more evenly and reduce hot spots. For designers working with thin acrylic panels or logo backlighting, this is a big advantage.

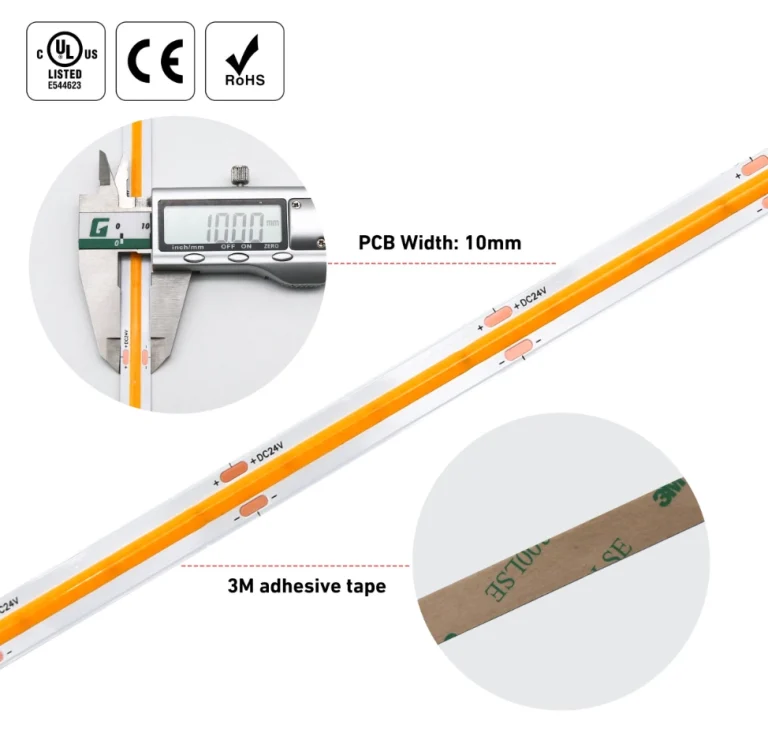

Certified Quality with UL CE RoHS Compliance

Raymates LED sheets come with certifications such as UL, CE, and RoHS. These are accepted in markets like Europe and North America. For buyers, this means less trouble with compliance and safer use.

How Can LED Sheets Enhance Creative Design

Support for Curved and Irregular Surfaces

Modern design often uses shapes that are not flat or square. LED sheets can bend to follow these curves. That allows designers to finally turn sketches into real installations.

Dynamic Lighting Effects and Smart Control

Although LED sheets are often used for simple backlighting, they can be paired with smart controllers. This opens options like dimming, changing color, or timed effects. A brand can set different lighting moods in the morning and evening, adding subtle value to customer experience.

Suitable for Large Scale and Logo Shaped Projects

Branding often requires unique lighting. LED sheets can be shaped to highlight logos or oversized surfaces. Raymates has completed logo-shaped projects with strong batch consistency. The color temperature stayed the same across all panels, avoiding the common mismatch problem.

Where Are LED Sheets Most Widely Applied Today

Cosmetics Counters and Luxury Retail Displays

Cosmetic brands rely heavily on lighting. Raymates LED sheets are already used in beauty counters in Asia and Europe. Accurate light makes products look appealing and helps sales.

Hotels Restaurants and Hospitality Spaces

Hotels and restaurants depend on atmosphere. Warm white LED sheets installed under reception desks or bar counters create a welcoming mood. They also require little maintenance.

Architectural Features and Decorative Surfaces

Architects increasingly include LED sheets in feature walls, ceilings, or artistic surfaces. Their thin profile makes them useful for updating old buildings without heavy construction.

Why Choose Raymates as Your LED Sheet Supplier

Global Market Recognition and Export Experience

Raymates exports to more than 30 countries, including the USA, Germany, and Saudi Arabia. Their sales team knows how to handle international documents and local standards.

Strong OEM and ODM Customization Capabilities

Many projects need non-standard products. Raymates supports OEM and ODM clients with custom voltages, sizes, or colors. For smaller companies, this flexibility can be critical for new designs.

Professional Engineering and After Sales Support

Raymates provides installation guides, video help, and quick service. In the lighting industry, a delay can cost time and money. Having a reliable partner makes a real difference.

FAQs

Q1: Can LED sheets be cut to any size?

Raymates LED sheets can be cut at specific marked points. Cutting outside these areas may cause damage, so following the guides is important.

Q2: Are LED sheets suitable for outdoor use?

Most standard LED sheets are made for indoor projects. For outdoor or wet environments, Raymates offers waterproof options with higher protection ratings.

Q3: How do LED sheets compare in cost with LED strips?

At first, LED sheets may cost more. But the even lighting, long lifespan, and easier setup often make them more cost-effective in large projects.