Lighting is one of those details people usually don’t think about until something goes wrong. A fixture doesn’t fit, the wiring takes too long, or the final glow looks patchy and uneven. For contractors, designers, and even DIY enthusiasts, installation time is money.

That’s where Light Tape and LED sheets have started to change the game. Instead of heavy fixtures and hours of labor, you get thin, flexible panels that stick, bend, and shine exactly where you need them. Raymates, a company that has been building LED solutions since 2009, knows this story all too well. Their MATRIX LED Sheet and LENSED LED Sheet are two good examples of why installing light can finally feel effortless.

What makes Light Tape so easy to apply

Ultra thin and flexible sheet design

Anyone who has tried to fit a rigid panel under a marble countertop knows the frustration of sharp corners and wasted material. Light Tape solves this by being just a couple of millimeters thick. Raymates’ LED sheets are not only slim but also bendable. That means you can follow curved bar counters, rounded display cases, or even uneven walls without fighting against the material. It feels a bit like working with wallpaper—except it glows.

Pre marked cut lines for precise sizing

You don’t always need a full panel. Sometimes a client wants just a strip of light under a shelf or around a mirror frame. LED sheets with pre-marked cut points (often every few LEDs) make this simple. There’s no guesswork or messy trimming. One of Raymates’ customers used this feature for a custom retail counter in Paris. They literally cut the MATRIX LED Sheet like craft paper, fitted it into the wood groove, and it lit up instantly.

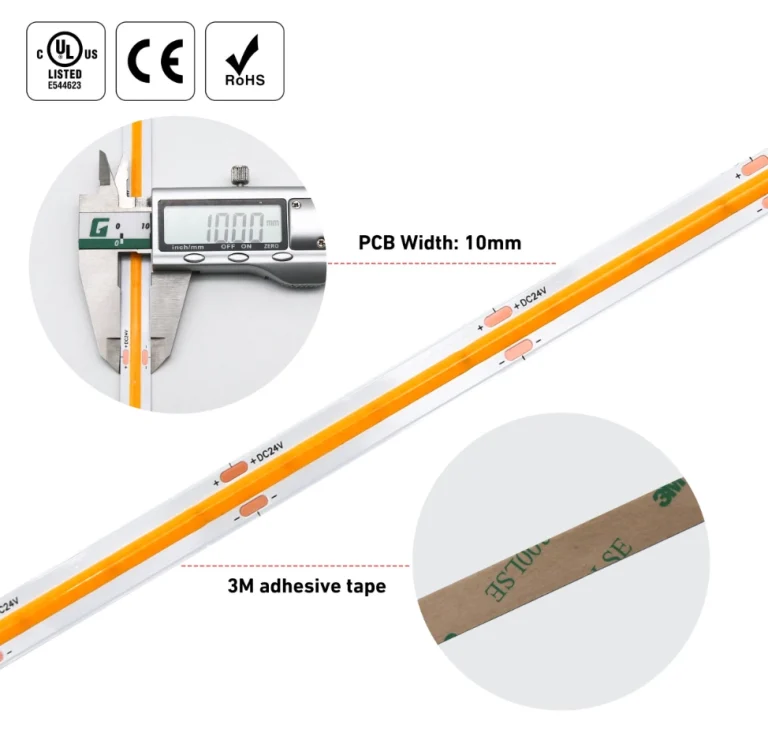

Peel and stick adhesive backing

Ask any installer what takes the most time, and many will say “fixing the light source in place.” Drilling holes and mounting brackets can eat up hours. Light Tape and flexible LED sheets skip that step. With a peel-and-stick adhesive backing, you press the panel in place and move on. Raymates usually recommends using 3M industrial-grade tape for long-term projects, and in high-humidity areas, a touch of silicone sealant keeps everything snug.

How do LED sheets simplify installation compared to traditional lighting

Uniform light without bulky fixtures

Conventional fluorescent boxes and spotlights need diffusers and layers to avoid hot spots. LED sheets, by design, spread light evenly. This makes them perfect for lightboxes, menu boards, or even backlit stone. One hotel client placed Raymates’ LENSED LED Sheet under a translucent onyx bar counter. The result? A warm, glowing surface with no visible dots, just a clean sheet of light.

Simple wiring and plug and play setup

Wiring used to mean bundles of cables, transformers, and plenty of trial and error. LED sheets now come with straightforward connectors. Many of Raymates’ projects in Europe use pre-soldered plug-and-play setups that cut wiring time in half. A single driver powers large sections, so you don’t need to connect dozens of strips.

Lightweight panels that reduce labor

Carrying heavy fixtures up ladders or scaffolding isn’t just tiring, it’s risky. A lightweight sheet changes that. A panel of less than 2 kg can be lifted with one hand, freeing the other for positioning. This is especially handy in retail stores where installation happens overnight to avoid business disruption.

Why is Raymates Light Tape trusted in commercial projects

Certified quality with UL and CE standards

It’s one thing to claim safety, it’s another to back it with certifications. Raymates has UL, CE, RoHS, and TUV approvals, which matter when bidding for international projects. These stamps of approval let contractors install without worrying about compliance issues later.

Proven durability with 50000 hour lifespan

A lighting project isn’t just about the first glow; it’s about how long it lasts. Raymates’ LED sheets are rated at 50,000 hours. That’s roughly 10 years if you run them 12 hours a day. For hotels, airports, or casinos, this means fewer replacements and lower maintenance costs.

Wide adoption in retail and hospitality lighting

From luxury shops in Dubai to boutique cafés in Berlin, Raymates products are already on the ground. One retail chain in Spain used the MATRIX LED Sheet for backlighting 200 store signs. The feedback? Faster installs and fewer maintenance calls compared to their old fluorescent setup.

How does the Matrix LED Sheet improve installation speed

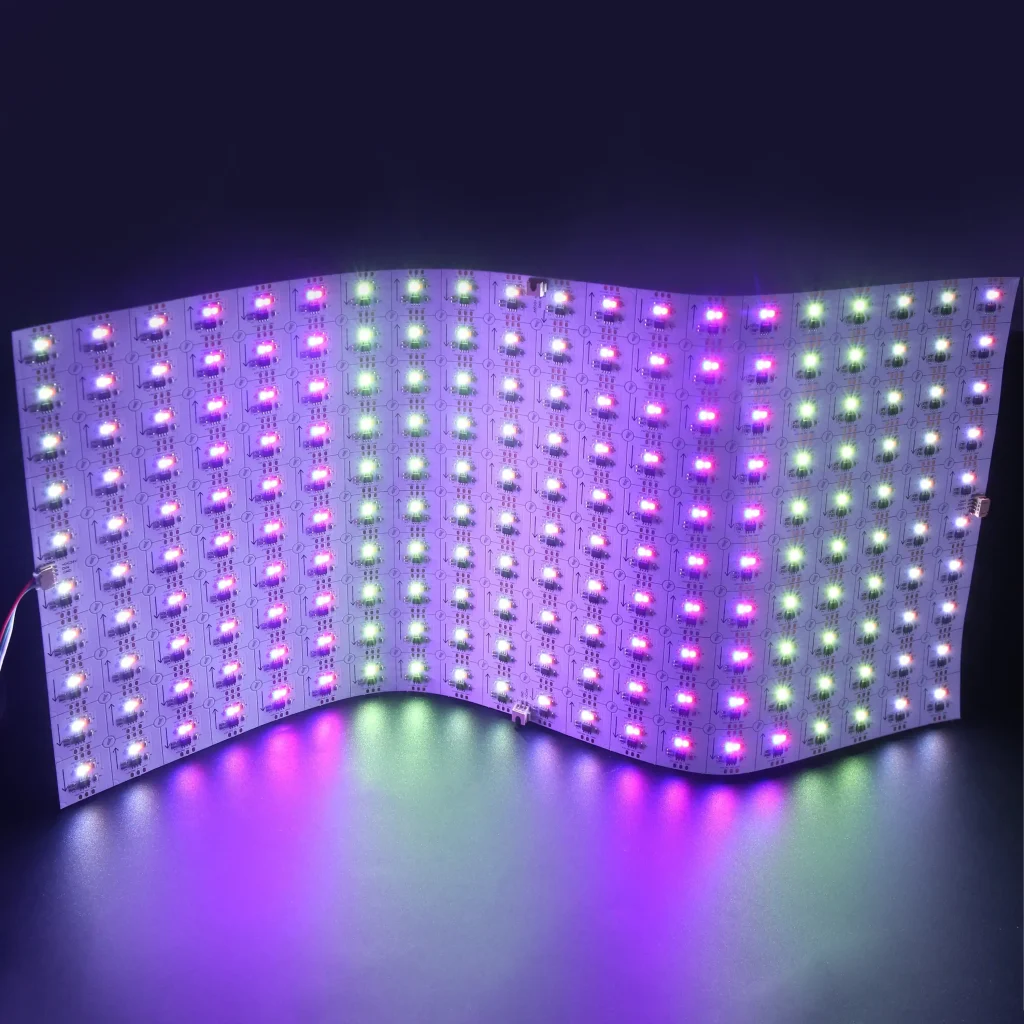

Grid layout that eliminates dark spots

One of the biggest complaints with older LED panels was uneven light. The MATRIX LED Sheet uses a tight grid pattern with even diode spacing. This removes shadows, which is crucial when you’re lighting brand signage or translucent stone.

Flexible fit for curved and irregular surfaces

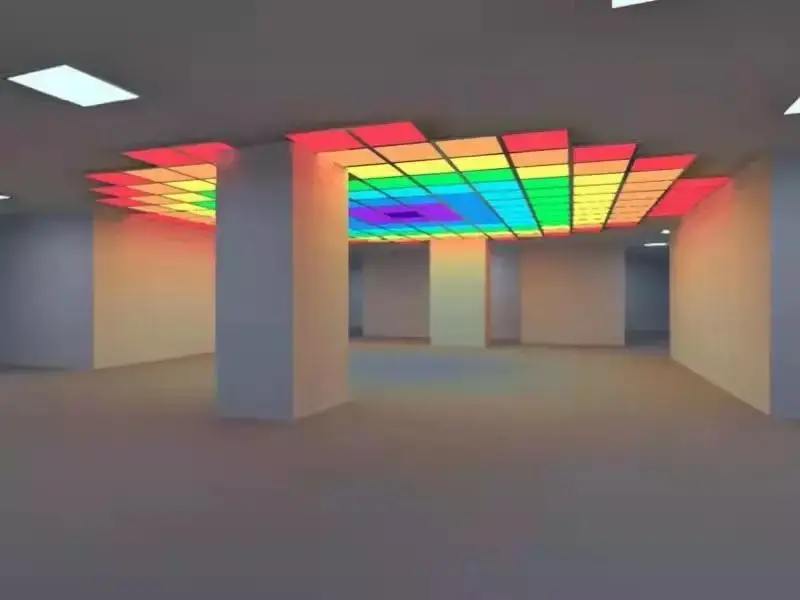

Not every project is square or flat. The MATRIX LED Sheet bends around corners and wraps edges. Designers often use it for curved reception desks or rounded feature walls, places where traditional lights would require custom fabrication.

Easy customization for large area projects

Need to cover an entire wall? The MATRIX LED Sheet can be tiled like wallpaper. Each piece connects seamlessly, letting installers scale up without complicated recalculations. For one exhibition hall project in Shanghai, a team installed 50 square meters of backlit panels in just two nights.

What benefits does the Lensed LED Sheet bring to installers

Built in optical lens for even brightness

The LENSED LED Sheet has tiny lenses over each diode. These spread the light at wider angles, cutting glare and giving surfaces a softer glow. It’s especially effective for displays where you want the product, not the light source, to catch attention.

Reduced hot spots on stone and glass surfaces

Stone, glass, and acrylic all show imperfections in lighting. The lens design diffuses the light so there are no harsh dots. This makes it the go-to choice for high-end stone counters and translucent walls.

Ready to use design with minimal adjustments

Unlike some panels that need diffusers or extra spacing, the LENSED LED Sheet comes ready to mount. Many installers like it because you spend less time fiddling with add-ons and more time finishing the project.

Where can Light Tape and LED sheets be used with ease

Backlit countertops and luxury interiors

Hotels often want glowing stone bars, while homeowners might want a marble kitchen island with subtle lighting. Both can be done with a single sheet tucked underneath.

Retail displays and brand signage

Think of cosmetics counters, jewelry displays, or branded shopfronts. LED sheets give even, bright backlighting that makes products pop without bulky fixtures in the way.

Hotels restaurants and entertainment venues

From creating moods in a KTV lounge to highlighting wine racks in a fine dining restaurant, LED sheets add atmosphere quickly. One restaurant in Toronto even used them under glass floors for a glowing runway effect.

How do easy installations translate into real value for clients

Lower labor costs and faster project delivery

Every hour saved in installation is money back in the client’s pocket. With peel-and-stick panels and plug-in drivers, projects move from weeks to days.

Reliable performance with minimal maintenance

Downtime hurts businesses. A light that needs constant fixing is not just annoying, it’s lost revenue. LED sheets with 50,000-hour lifespans avoid that headache.

Enhanced aesthetics that boost customer satisfaction

In the end, what matters is how people feel in the space. Uniform, warm lighting creates comfort, luxury, and sometimes even sales. A well-lit store keeps customers browsing longer.

FAQ

Q1: Can Raymates LED sheets be cut to fit custom sizes?

Yes. Both MATRIX and LENSED LED Sheets have marked cutting lines, making it simple to size panels to unique dimensions without damaging the circuit.

Q2: Are these LED sheets suitable for outdoor use?

Standard sheets are designed for indoor use. However, with protective housing or custom waterproofing options, Raymates can supply solutions for semi-outdoor applications.

Q3: How long does installation typically take for a medium project?

For a retail counter or bar top, most installers report completing the lighting in just a few hours, far less than traditional fixture-based setups.